Dredging plays a crucial role in maintaining navigable waterways, reclaiming land, and removing sediments to protect the environment. Whether it’s in ports, rivers, or construction sites, selecting the right equipment is essential for maximizing efficiency and ensuring project success. This guide provides an in-depth look at the various dredging equipment types and their uses, helping you make informed decisions for your next project.

What is Dredging?

Dredging is the process of removing sediment, debris, and other materials from the bottom of bodies of water. It’s commonly employed for deepening ports and harbors, maintaining navigable waterways, land reclamation, and environmental remediation. Over time, sediment builds up in these areas, reducing their depth and limiting access for ships or causing environmental concerns like flooding or habitat destruction.

Proper equipment is needed for everything from marine construction to mining and environmental cleanup. Selecting the correct machinery, along with essential dredging accessories, can significantly impact the project’s outcome. Whether you’re working on a large-scale marine construction project or a smaller environmental cleanup effort, choosing the appropriate dredging equipment types is key to ensuring that the work is done efficiently and effectively.

Overview of Dredging Equipment

Dredging equipment generally falls into two main categories: mechanical and hydraulic. Each type has unique characteristics that make it suited to specific tasks, project sizes, and material types.

- Mechanical Dredging Equipment: Involves physically scooping or lifting materials from the seabed. It’s most effective for compacted or hard materials.

- Hydraulic Dredging Equipment: Uses suction to transport sediments and other materials through a pipeline. It’s ideal for loose or fine-grained materials.

Understanding these categories is essential for matching the equipment types to the specific demands of your project. Additional dredging accessories like cutter heads or trailing arms can further enhance the efficiency of the process.

Mechanical Dredging Equipment

1. Backhoe Dredgers

Backhoe dredgers are equipped with an excavator arm mounted on a barge or vessel. These machines work similarly to an excavator on land, using their arm to scoop materials from the seabed and deposit them onshore or into a barge for disposal. Backhoe dredgers are ideal for shallow-water operations and can handle tough materials such as rock, clay, and gravel. They are widely used in harbor maintenance and construction projects where precision excavation is required.

Common Uses: Harbor maintenance, excavation of hard materials, and clearing confined areas.

2. Clamshell Dredgers

Clamshell dredgers operate using a bucket that opens and closes like a clamshell. The bucket is lowered to the seabed, where it scoops up material, which is then lifted to the surface. This equipment type is well-suited for handling loose, coarse materials like gravel and sand. It’s also a popular choice for dredging in shallow waters and for projects where access is limited.

Common Uses: Shallow-water operations, handling coarse materials, small-scale dredging projects.

3. Bucket Ladder Dredgers

Bucket ladder dredgers consist of a continuous chain of buckets attached to a ladder that rotates around a structure. The buckets scoop material from the seabed as they move along the ladder, and the material is transported to a barge or deposit area. Although not as widely used in modern dredging projects, bucket ladder dredgers were historically popular for continuous excavation.

Common Uses: Historic dredging applications and specialized excavation projects.

Hydraulic Dredging Equipment

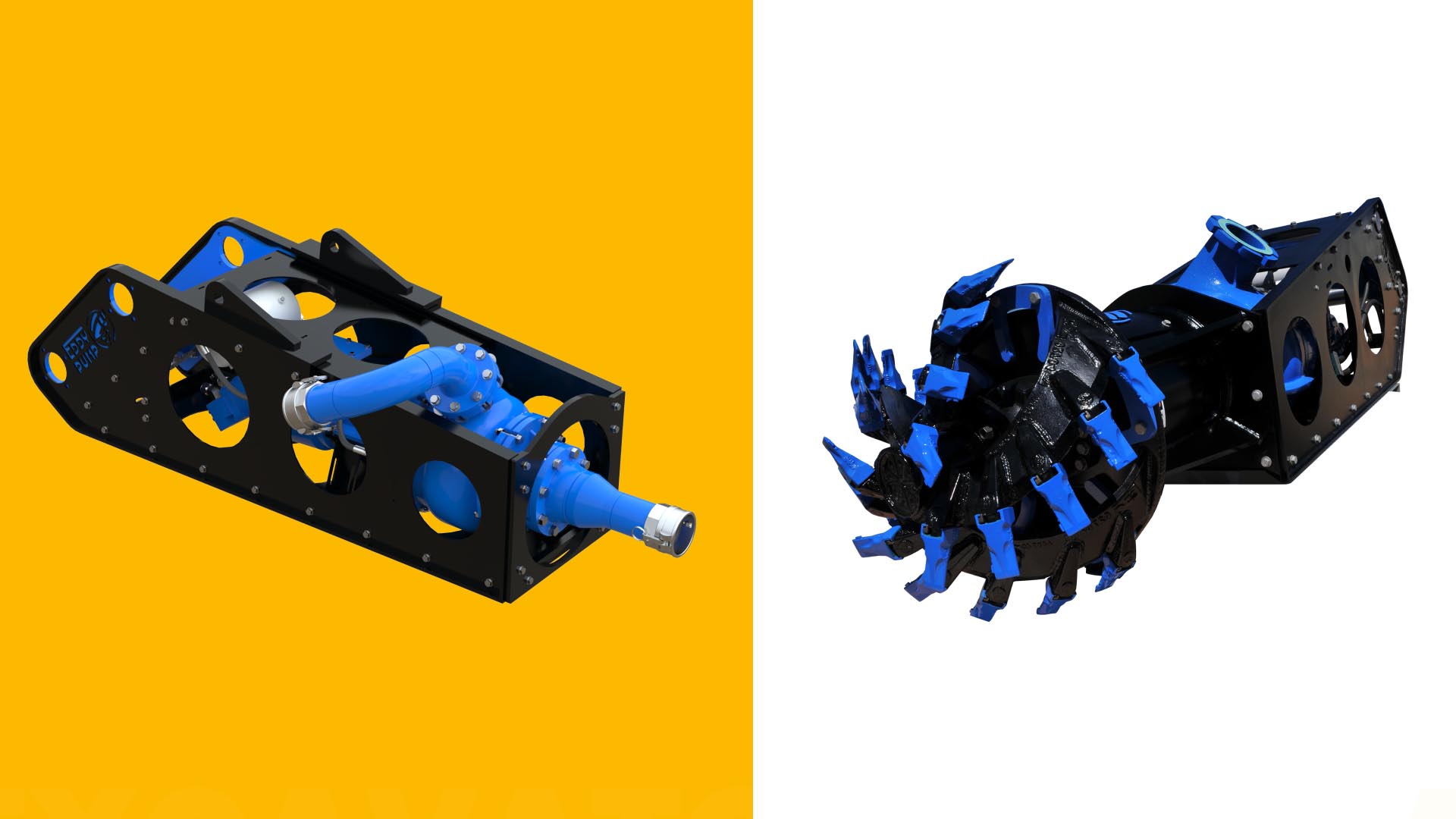

1. Cutter Suction Dredgers (CSD)

Cutter suction dredgers use a rotating cutter head to break up compact material such as clay, rock, or other dense sediments. Once the material is loosened, it is immediately suctioned up through a pipe and transported to a designated area. This is highly effective for large-scale projects where removing solid material is a challenge. The combination of cutting and suction makes it one of the most versatile dredging tools available today.

Common Uses: Large-scale dredging projects, removing compact or dense material, reclamation projects.

2. Suction Dredgers

Suction dredgers, unlike their cutter suction counterparts, do not have a cutter head. These machines rely solely on suction to remove loose sediment from the seabed. While not suitable for harder materials, hydraulic dredging equipment like suction dredgers are ideal for sand, silt, and other fine-grained materials. These dredgers are often used in river maintenance and coastal projects.

Common Uses: River dredging, removing soft sediments, coastal maintenance.

3. Trailing Suction Hopper Dredgers (TSHD)

TSHDs are self-propelled vessels equipped with suction pipes. These pipes are lowered into the water to suck up sediment, which is stored in the hopper of the vessel. Once the hopper is full, the dredger travels to the disposal site to release the material. TSHDs are ideal for deep-water dredging and large-scale projects that require high-capacity sediment removal. This hydraulic dredging equipment type is commonly used in coastal reclamation projects.

Common Uses: Deep-water dredging, land reclamation, large-scale sediment removal.

Specialized Dredging Equipment

1. Environmental Dredgers

Environmental dredgers are designed for precision and are used in projects that require minimal environmental disruption. These dredgers often feature advanced control systems to minimize sediment dispersion, making them ideal for projects aimed at environmental remediation and cleaning polluted water bodies. With the right dredging accessories, environmental dredgers can deliver high accuracy in sensitive areas.

Common Uses: Environmental cleanup, precision dredging, minimizing sediment disruption.

2. Amphibious Dredgers

Amphibious dredgers are versatile machines capable of operating both in water and on land. These dredgers are often used in marshes, wetlands, and shallow waters where other equipment would be ineffective. Their mobility makes them suitable for projects where access is challenging.

Common Uses: Marshland restoration, wetland dredging, shallow water operations.

3. Mini Dredges

Mini dredges are small, portable machines used for small-scale dredging projects. These compact dredgers are ideal for clearing ponds, small lakes, and other confined water bodies. They are often used in recreational areas for water maintenance and sediment removal.

Common Uses: Pond dredging, recreational waterway maintenance, small-scale projects.

Choosing the Right Dredging Equipment for Your Project

Selecting the right dredging equipment types depends on several factors, including the size of the project, the type of material to be dredged, and environmental considerations. Here are some key aspects to keep in mind:

- Material Type: Dense materials like clay and rock require mechanical dredgers like backhoes and cutter suction dredgers, while loose materials like sand and silt are best handled by hydraulic dredging equipment.

- Project Size: Large-scale projects often call for high-capacity dredging equipment types such as TSHDs or cutter suction dredgers. Smaller projects can benefit from mini dredges or clamshell dredgers.

- Environmental Impact: For projects in sensitive areas, consider environmental dredgers equipped with the right dredging accessories to minimize sediment disruption and pollution.

Conclusion

Understanding the different dredging equipment types is essential for matching the right tool to the specific requirements of your project. From backhoe and clamshell dredgers for mechanical excavation to hydraulic equipment like cutter suction and TSHDs for large-scale operations, each type of equipment offers unique benefits. By carefully considering project goals, material types, and environmental factors, you can choose the most effective dredging equipment and dredging accessories to ensure your project’s success.

Post a Comment