Description

The Komatsu PC360 excavator is engineered for robust performance in construction, mining, and various heavy-duty excavation applications. Its design incorporates advanced features that enhance its capability to perform tasks such as trenching, foundation digging, grading, and land leveling.

Key to its functionality is the high-performance hydraulic system, which provides exceptional digging and lifting power. The system utilizes high-pressure hydraulic fluid to actuate the arm, bucket, and other attachments, enabling precise and smooth operation. This hydraulic setup allows the excavator to manage substantial loads and heavy materials efficiently.

The Komatsu PC360 is also optimized for maintenance and repair operations. It features components designed for accessibility, simplifying service procedures. A comprehensive maintenance manual accompanies the excavator, offering detailed instructions for routine servicing and repairs. Additionally, the integrated diagnostic system facilitates rapid identification and troubleshooting of issues, minimizing machine downtime and ensuring operational efficiency.

Komatsu PC360 Excavator Features

Large Displacement High-Efficiency Pump: This pump features high-flow hydraulic implement pumps with large displacement, optimizing output at lower engine RPMs for enhanced operational efficiency.

Closed-Center Load-Sensing Hydraulic System: This system incorporates a closed-center load-sensing hydraulic system that ensures smooth operation, rapid cycle times, and effective multi-functioning while reducing fuel consumption.

Structural Durability: Engineered for long-term durability, the Komatsu PC210 excavator is constructed with high-tensile strength steel. It features booms and arms with thick plates and large cross-sectional areas to resist bending and torsional stress.

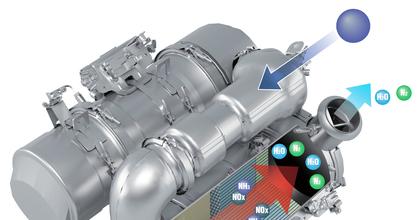

Emission Control: Equipped with a heavy-duty aftertreatment system that integrates a Komatsu Diesel Particulate Filter (KDPF) and Selective Catalytic Reduction (SCR). This system precisely injects diesel exhaust fluid to decompose nitrogen oxides.

Maintenance Access: Engine oil check and filter locations are consolidated on one side for streamlined maintenance access.

Ergonomic Design: The cab features a spacious layout with a heated air suspension seat and a reclining backrest. The seat height and position are adjustable via a pull-up lever, and armrest positioning is adjustable with the console.

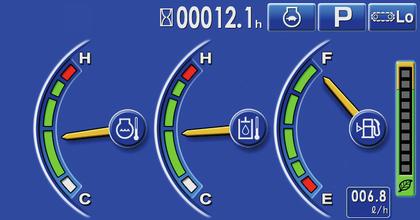

User Interface: The vehicle has been updated with a large, high-resolution LCD color monitor that provides a user-friendly interface. The monitor displays key machine information, including rearview camera footage and a DEF level gauge.

Rollover Protection: Standard ROPS cab conforming to ISO 12117-2 standards, meeting Level 1 Operator Protective Guard (OPG) and top guard requirements per ISO 10262.

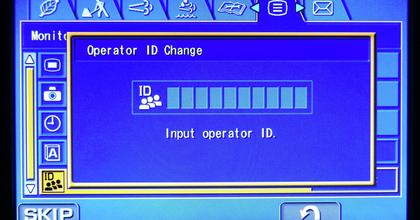

Operator Productivity: Supports operator identification IDs to manage and analyze operation data for individual machines via Komtrax data, enabling performance analysis by operator and machine.

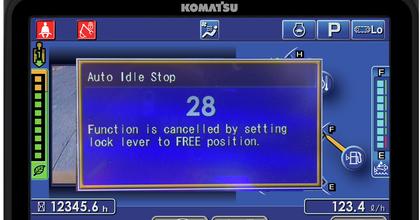

Fuel Consumption Reduction: The auto idle shutdown feature deactivates the engine after a preset idle period (5 to 60 minutes) to minimize fuel consumption and exhaust emissions.

Component Protection: Equipped with large, heavy-duty revolving frame guards and swivel guards to protect critical components from damage and debris accumulation.

Maintenance and Serviceability: A new step for AdBlue/DEF tank filling facilitates easier maintenance access and provides a secure work area in front of the engine.

Reviews

There are no reviews yet.