Description

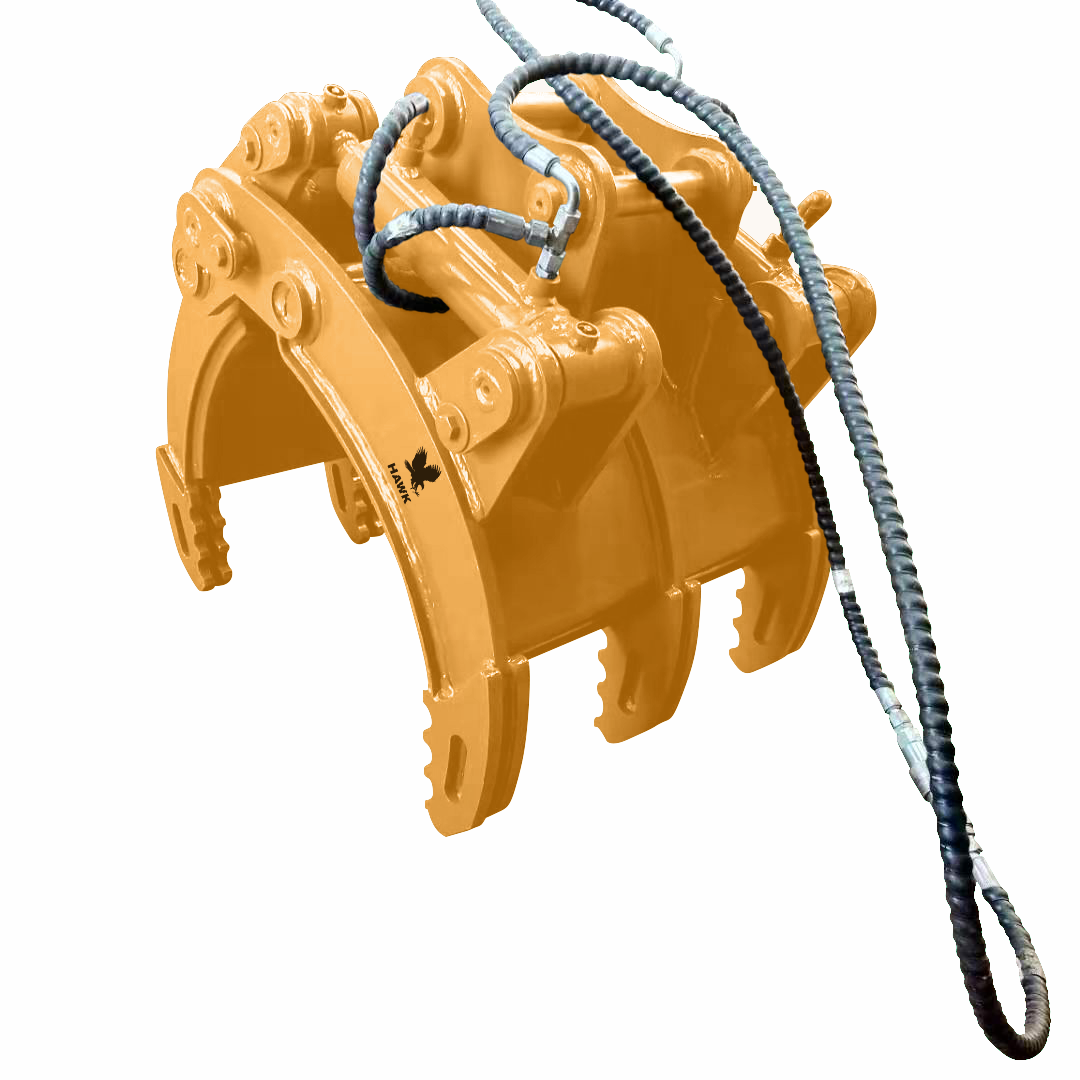

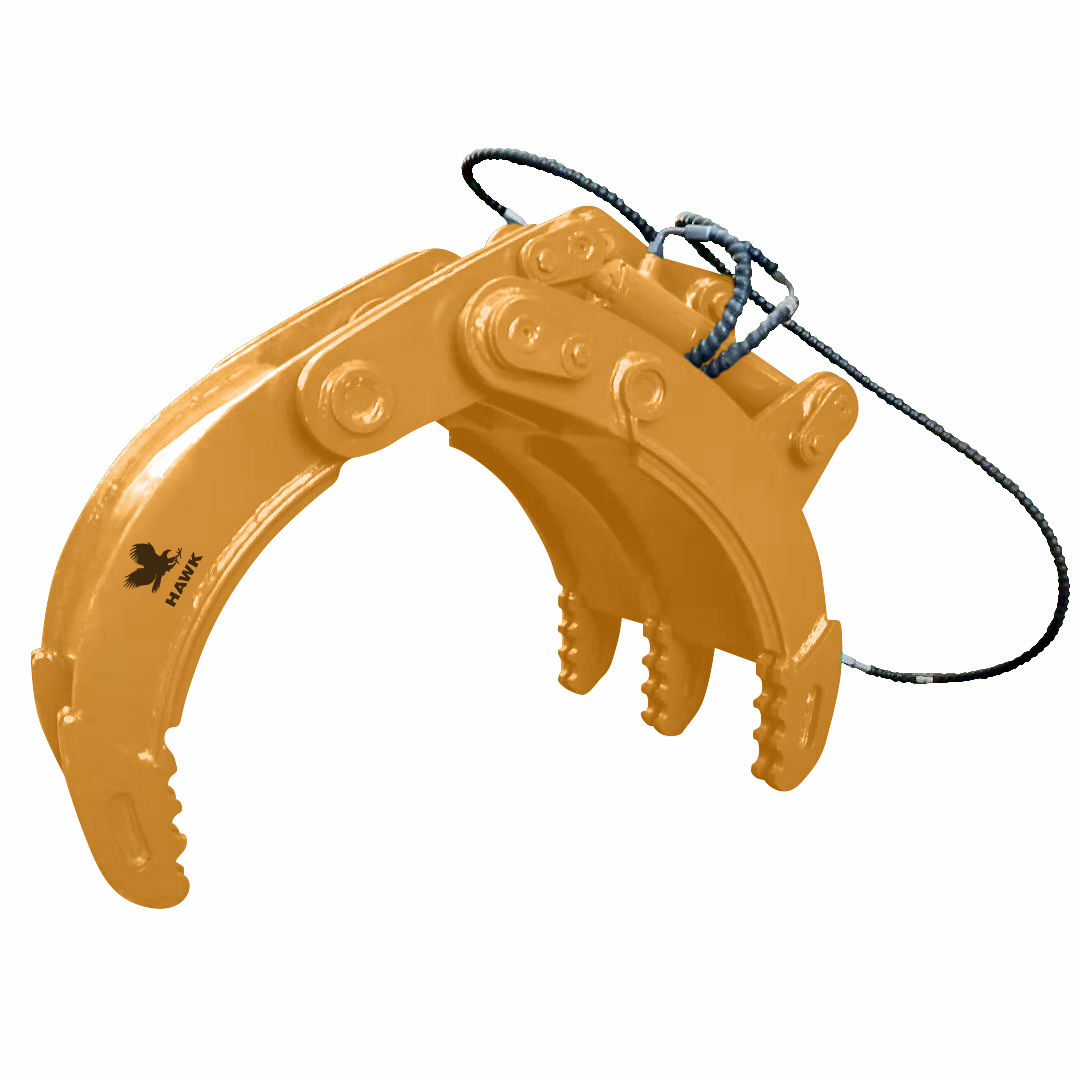

The HAWK Excavator Hitachi EX120 Mechanical Grapple is indispensable for mining, demolitions, excavations, and construction operations, facilitating efficient material loading and unloading. Crafted to endure rigorous daily use, these attachments are constructed from premium materials, ensuring durability in challenging conditions.

The HAWK Hitachi EX120 Mechanical Grapple is engineered to deliver exceptional gripping strength and stability, enabling operators to confidently handle a diverse range of tasks. Its versatile design enables precise control and maneuverability, ensuring seamless operation across various applications.

Installation and setup are streamlined, allowing for quick attachment of the mechanical grapple to the excavator with minimal downtime. This swift setup process maximizes operational efficiency and productivity on the job site.

With a durable coating, our mechanical grapples exhibit resistance to corrosion and wear, ensuring prolonged performance even in harsh operating environments. Additionally, optional features and accessories are available, allowing for customization to meet individual preferences and requirements.

Specifications:

- Model: HITEX120-MG80

- Full Open: 59.1 in (1500 mm)

- Fixed Jaw Width: 35.2 in (894 mm)

- Moving Jaw Width: 20.4 in (517 mm)

- Connection Rob Length: 47.2 in (1200 mm)

- Height: 44.3 in (1125 mm)

- Weight: 1300.7 lbs (590 kg)

- Material: Q355+NM400

- Excavator Compatibility: Hitachi EX120

Benefits of Hitachi EX120 Mechanical Grapple

Enhanced Versatility: The Hitachi EX120 Mechanical Grapple Attachment from Hawk Excavator offers exceptional versatility on the job site, securely gripping and lifting various materials like logs, rocks, and debris, due to its robust design.

Increased Productivity: By optimizing material handling tasks, this Mechanical Grapple Attachment significantly enhances worksite productivity, enabling operators to swiftly grab and maneuver objects, thus minimizing downtime.

Precision Control: Equipped with advanced control features, this Mechanical Grapple Attachment allows operators to achieve precise and controlled movements, enhancing accuracy during material handling tasks and minimizing rework.

Safety Assurance: Safety is prioritized in any excavation operation, with all Hawk Excavator Mechanical Grapple Attachments featuring secure gripping mechanisms and built-in safety features to minimize accidents and ensure a safe working environment.

Cost-Effectiveness: Investing in a Hawk Mechanical Grapple Attachment proves cost-effective for contractors and operators, as it streamlines operations, reduces labor requirements, and boosts productivity, leading to significant cost savings over time.

Ease of Maintenance: The Hitachi EX120 Mechanical Grapple Attachment is designed for ease of maintenance, with accessible components and simple maintenance procedures, allowing operators to keep it in optimal condition with minimal effort.

Features of the Hitachi EX120 Mechanical Grapple

Customized Design: Specifically engineered to fit the Hitachi EX120 excavator model, this Mechanical Grapple Attachment ensures seamless integration and optimized performance with the machine’s capabilities.

Robust Construction: Crafted from high-quality materials and built to withstand heavy-duty use, this Mechanical Grapple Attachment offers exceptional durability and reliability in demanding working conditions.

Versatile Grip: Equipped with powerful jaws and hydraulic mechanisms, the grapple attachment provides a versatile grip capable of securely holding various materials such as logs, rocks, debris, and more, enabling efficient handling on the job site.

Precise Control: Operators benefit from precise control over this Mechanical Grapple Attachment, allowing for accurate positioning and manipulation of materials. This precise control enhances productivity and minimizes the risk of damage to surrounding structures or equipment.

Quick Attachment System: With a quick attachment system, the Hitachi EX120 Mechanical Grapple Attachment enables swift installation and removal, minimizing downtime between tasks and maximizing equipment utilization on the job site.

Reviews

There are no reviews yet.