Description

HDPE DR11 pipe is highly advantageous for various industrial applications due to its high-density polyethylene composition, which ensures exceptional durability and corrosion resistance. With a DR11 thickness, it is one of the most robust grades of HDPE pipe available.

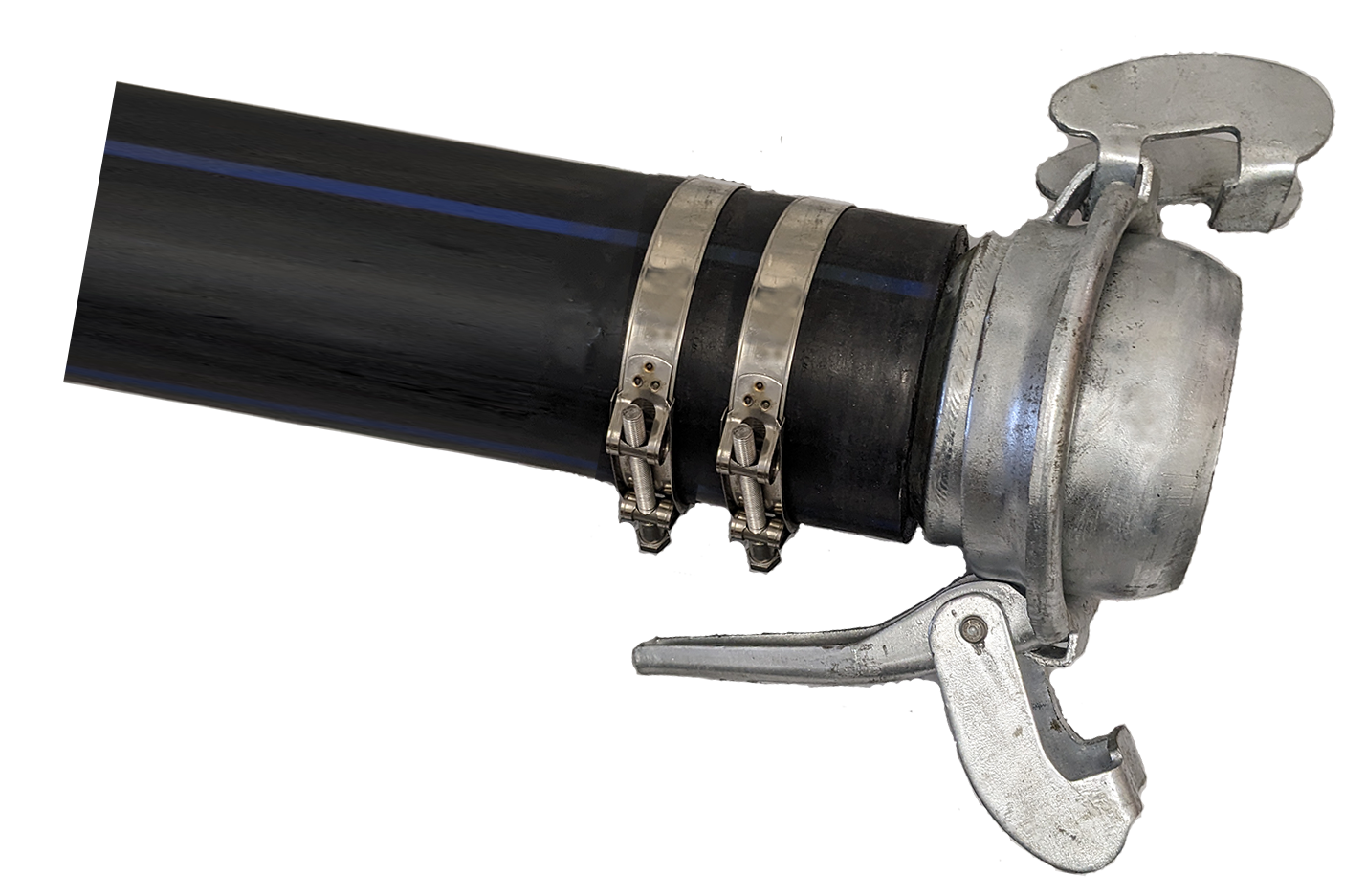

Standard Bauer fittings enable quick connections and disconnections, which is crucial for short-term or time-sensitive projects.

The smooth interior surface of the HDPE DR11 pipe promotes efficient fluid flow, reducing friction and enhancing overall system performance. Additionally, its lightweight design facilitates easy handling and installation, minimizing labor costs.

Many Anaconda customers utilize our HDPE DR11 pipe solutions for temporary projects. We offer the flexibility of renting our pipe and hose solutions, allowing for easy inventory return once a project is complete. Contact us for details.

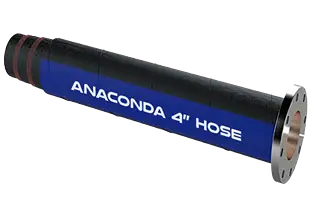

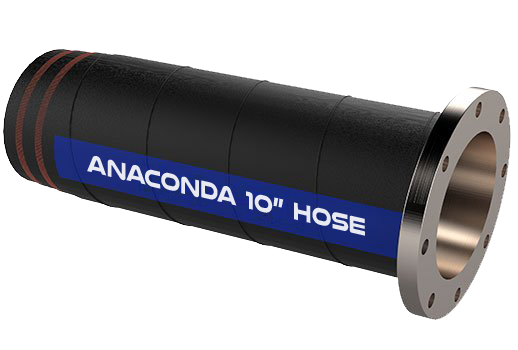

This pipe is available in 36-foot (11-meter) sections, and quotes are based on the entire length.

HDPE DR11 pipe comes standard with Bauer fittings but can be customized to feature ANSI Flanges or no fitting.

HDPE Pipe Benefits

Anaconda Pipe & Hose offers industrial HDPE DR11 pipe solutions designed to meet diverse application requirements. The following technical features distinguish our HDPE pipes:

Bauer Fittings: Facilitate easy connection and disconnection, enabling the creation of modular pipeline systems that can be rapidly deployed and adapted to changing dredging needs.

Materials and Construction: Crafted from high-quality materials for durability and longevity in challenging industrial environments.

Pressure and Temperature Ratings: Can handle varying pressure levels and broad temperature ranges, ensuring reliable fluid conveyance in diverse conditions.

Corrosion Resistance: Extremely corrosion-resistant, extending lifespan and maintaining optimal performance in corrosive environments.

Dimensional Accuracy: It is manufactured with precise measurements to seamlessly integrate with fittings and equipment, minimizing the risk of leaks or inefficiencies.

Flexibility and Rigidity: Offer a range of flexibility options while maintaining structural integrity to prevent collapse or deformation during operation.

Quality Assurance: Undergo rigorous quality control and testing procedures to ensure compliance with industry standards and optimal performance.

Anaconda Pipe & Hose’s industrial HDPE DR11 pipes prioritize durability, performance, and versatility, meeting the demanding requirements of modern industrial processes for reliable solutions across various applications.

Industries

Industrial HDPE DR11 pipe is essential across various industries, offering versatile solutions for fluid transport, material conveyance, and structural applications. Here is a technical description of the primary industries where industrial HDPE DR11 pipe finds extensive use:

1. Oil and Gas Industry:

Application: Transmission of crude oil, natural gas, and other hydrocarbons.

Industrial HDPE DR11 pipe in this sector withstands high-pressure environments, features corrosion-resistant coatings, and meets stringent material specifications for safe and efficient fossil fuel transportation.

2. Chemical Processing Industry:

Application: Conveyance of chemicals, acids, and corrosive substances.

Engineered with materials resistant to chemical corrosion, ensuring pipe integrity and preventing contamination during fluid transfer.

3. Manufacturing and Processing:

Application: Material transport within manufacturing plants and industrial processes.

HDPE DR11 pipe offers precise dimensions, varying flexibility, and compatibility with different materials, facilitating efficient and controlled material flow in diverse production settings.

4. Water and Wastewater Industry:

Application: Distribution of clean water and conveyance of wastewater.

Features materials resistant to corrosion and contaminants, complying with stringent standards for safe and reliable water transport in municipal and industrial systems.

5. Construction Industry:

Application: Structural support, water supply, and material transport on construction sites.

Offers key structural integrity and durability benefits, suitable for scaffolding, underground utilities, or conduits for various construction materials.

6. Mining Industry:

Application: Transport of ores, minerals, and slurry in mining operations.

It is designed to handle abrasive materials, high pressures, and challenging terrain. Its abrasion-resistant coatings and robust construction ensure longevity in demanding environments.

- 7. Power Generation:

Application: Transport fluids in power plants, including steam and cooling water.

Endures high temperatures and pressures, often designed with materials suitable for steam transport and offering corrosion-resistant coatings for longevity.

8. Agriculture and Irrigation:

Application: Conveyance of water for irrigation, fertilizers, and pesticides.

Requires flexibility, durability, and UV resistance, utilized in irrigation systems for efficient water distribution in agricultural fields.

9. Food and Beverage Industry:

Application: Transport of liquids in food and beverage processing plants.

Made from materials compliant with food-grade standards, preventing contamination and maintaining hygienic standards in food processing.

10. Automotive and Aerospace Manufacturing:

Application: In manufacturing, precision, and resistance to hydraulic fluids and coolants are required.

It plays a crucial role in maintaining manufacturing system efficiency.

Industrial HDPE DR11 pipe is indispensable in numerous industries, each demanding specific technical characteristics to meet the challenges of their applications. Whether conveying fluids, supporting structures, or facilitating manufacturing processes, HDPE DR11 pipe significantly contributes to industrial sectors’ seamless and efficient operation.

Available Pipe Fittings

Bauer Fittings, also known as Bauer Couplings, are versatile and reliable components in industrial pipe systems, offering several technical advantages for efficient fluid handling:

- Rapid and Secure Connection: Designed for quick coupling, Bauer fittings enable rapid connection and disconnection, reducing downtime. They ensure a secure, leak-free connection, enhancing system reliability and safety.

- Versatile Applications: Bauer Fittings are used across various industries, including agriculture, construction, dredging, and mining. They can connect pipes of different materials and sizes, providing a standardized solution for fluid transport needs.

- Durable Construction: Bauer Fittings are constructed from high-quality galvanized or stainless steel. They are durable and corrosion-resistant, able to withstand harsh industrial environments, and minimize the need for frequent replacements.

- Sealing Mechanism: Bauer Fittings incorporate a reliable sealing mechanism, such as EPDM or NBR gaskets, ensuring a tight seal. This makes them suitable for various fluids, including water, chemicals, and slurry.

- Pressure Ratings: Bauer Fittings are engineered to handle varying pressure requirements. They are available in different pressure classes, ensuring compatibility with various industrial systems.

- Ease of Handling and Operation: Bauer Fittings are designed for easy handling and operation. The quick-locking mechanism simplifies the connection process, requiring minimal effort from operators.

- Interchangeability: Bauer Fittings of the same size and type from different manufacturers can often be used interchangeably. This interchangeability enhances flexibility in sourcing components and simplifies maintenance and repairs.

- Reduced Maintenance Requirements: Bauer Fittings’ durability reduces maintenance needs. Their resistance to corrosion and wear minimizes the risk of component failure, resulting in lower maintenance costs and increased operational efficiency.

- Cost-Effective Solutions: Bauer Fittings offers cost-effective HDPE DR11 pipe connection solutions. Their ease of installation, interchangeability, and durability contribute to labor cost savings.

- Safety & User Friendly: Bauer fittings are designed with user safety in mind. The assembly process is straightforward, reducing the risk of accidents or injuries during pipeline connections and disconnections.

- Wide Range of Accessories: Bauer fittings come with various accessories, such as caps, plugs, and reducers, enhancing their versatility and allowing users to customize their pipe systems.

ANSI flange fittings adhere to American National Standards Institute (ANSI) specifications and offer several technical benefits for fluid handling:

- Standardized Design: ANSI flange fittings follow standardized dimensions and specifications, ensuring uniformity across manufacturers and allowing for interchangeability.

- Ease of Installation: The design of ANSI flange fittings facilitates easy installation and removal. The bolt-hole patterns and flange faces adhere to ANSI standards, enabling quick alignment and connection.

- Wide Range of Applications: ANSI flange fittings find application in diverse industries, including oil and gas, fisheries, and chemical processing. They are compatible with various pipe and hose materials and fluids.

- Durable Construction: ANSI flange fittings are made from materials such as carbon steel, stainless steel, or alloy steel, ensuring durability and corrosion resistance.

- Pressure and Temperature Ratings: ANSI flange fittings are engineered to meet specific pressure and temperature ratings, ensuring safe and reliable performance in various operating conditions.

- Sealing Mechanism: ANSI flange fittings incorporate a gasket sealing mechanism, ensuring a reliable and leak-free seal between mating flanges.

- Versatility in Flange Types: ANSI standards encompass various flange types, such as slip-on, weld neck, blind, and lap joint flanges, allowing users to choose the appropriate type based on their specific application.

- Facilitates Piping System Maintenance: The standardized design of ANSI flange fittings simplifies maintenance and repairs, enabling quick access to components.

- Compliance with Industry Standards: ANSI flange fittings adhere to industry standards, ensuring compliance with safety and quality requirements.

- Facilitates System Expansion: ANSI flange fittings allow for straightforward system expansion or modification, contributing to the adaptability and scalability of industrial installations.

While using straight lengths of HDPE DR11 pipe without fittings can offer certain benefits such as reduced friction, simplified maintenance, custom length configurations, and minimized risk of leakage, it’s crucial to consider specific project requirements and industry standards before making this choice. Consulting with engineers and adhering to best practices is essential to ensure the safety and efficiency of the piping system.

Reviews

There are no reviews yet.