Description

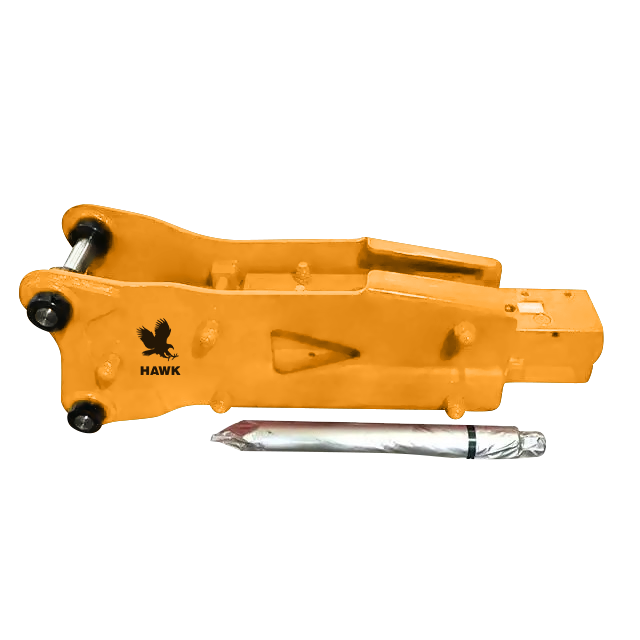

The HAWK HBH750T top hydraulic breaker hammer, equipped with a 3-inch chisel, is a crucial tool in mining, demolition, excavation, and quarrying operations, effectively chipping away large boulders and concrete structures.

Renowned for their high performance, these hydraulic hammers are favored by contractors and widely used on construction sites, offering efficiency and reducing manual labor. The HBH750T top breaker hammer by HAWK Excavator is designed for durability, efficiency, and reliability, making it a versatile solution for various construction needs.

Available in different sizes to fit a range of excavator makes and models, these breaker hammers are designed for easy setup and offer premium service support. The HAWK HBH750T Hydraulic Breaker Hammer is part of a series that includes various diameters, tonnages, working flows, and working pressures.

Excavator Tonnage: 6-9 Tons

Type: Top

Chisel Options: Moil point, Blunt, Flat chisel, Conical point

Product Specifications

Model: HBH750T

Excavator Weight: 6-9 Tons

Chisel Diameter: 3 in (75 mm)

Chisel Options: Moil point, Blunt, Flat chisel, Conical point

Chisel Quantity: 2

Operating Weight: 882 lbs. (400 kg)

Working Flow: 13-24 GPM (50-90 L/min)

Working Pressure: 1707-2418 PSI (120-170 kg/cm2)

Applications:

- Mining

- Demolition

- Construction

- Quarry

For Use On:

- Skid steer loader

- Backhoe loader

- Crane

- Telescopic handler

- Wheel loader

- Excavator

Benefits of Top Hydraulic Breaker Hammers

HBH750T top hydraulic breaker hammers offer several advantages for construction, demolition, and mining applications, including:

Increased productivity: These hammers deliver powerful impacts, efficiently breaking rock, concrete, and other materials, reducing the time and effort needed for tasks.

Versatility: Hydraulic breaker hammers are suitable for various applications, such as demolition, excavation, trenching, and breaking oversized materials. They can be mounted on different carriers, providing flexibility.

Low maintenance: With minimal moving parts, these hammers have reduced risks of mechanical failures, requiring less maintenance. The hydraulic system eliminates the need for a separate compressor or hoses, simplifying setup.

Low noise: HBH750T hydraulic breaker hammers produce less noise than pneumatic or mechanical hammers, making them suitable for urban areas or noise-sensitive environments.

Vibration control: Advanced vibration control systems minimize vibration transmitted to the carrier and operator, reducing fatigue and enhancing operator comfort and productivity.

Durability: These hammers are built with robust materials and components for long service life, even in challenging conditions.

Energy efficiency: Hydraulic breaker hammers use the hydraulic power of the carrier, which is more energy-efficient than pneumatic or mechanical systems. This results in lower fuel consumption and reduced emissions.

Easy attachment: Hydraulic breaker hammers can be easily attached to and detached from the carrier, allowing operators to easily switch between tools and tasks.

Features of Top Hydraulic Breaker Hammers

HBH750T top hydraulic breaker hammers have features that enhance their performance, durability, and usability. These features include:

High-impact energy: These hydraulic breaker hammers deliver powerful impacts, enabling efficient breaking of rigid materials such as rock, concrete, and asphalt.

Advanced vibration control: HAWK Excavator breakers incorporate vibration-dampening systems that reduce the vibration transmitted to the carrier and operator, minimizing fatigue and improving productivity.

Robust construction: These high-quality hydraulic breaker hammers are constructed from durable materials and components to withstand challenging working conditions and provide a long service life.

Variable frequency and energy control: Adjustable impact frequency and settings allow operators to customize the breaker’s performance for different materials and applications.

Noise reduction: HAWK Excavator’s top hydraulic breakers are designed to minimize noise levels during operation, making them suitable for use in urban areas or noise-sensitive environments.

Reviews

There are no reviews yet.