Description

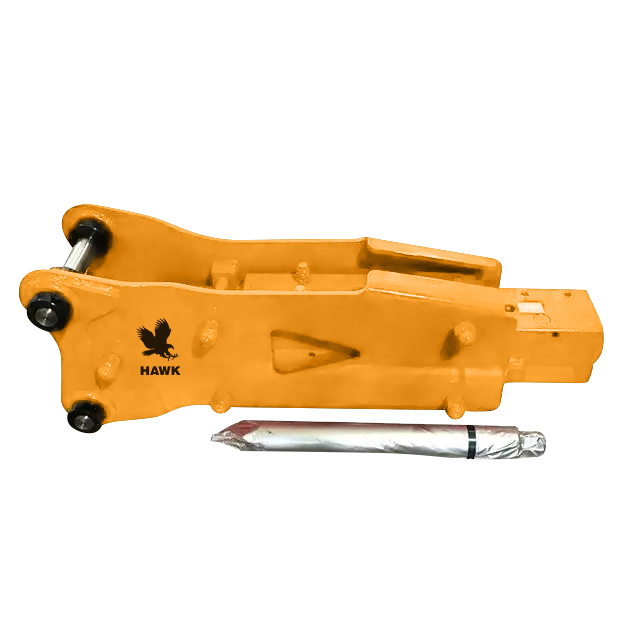

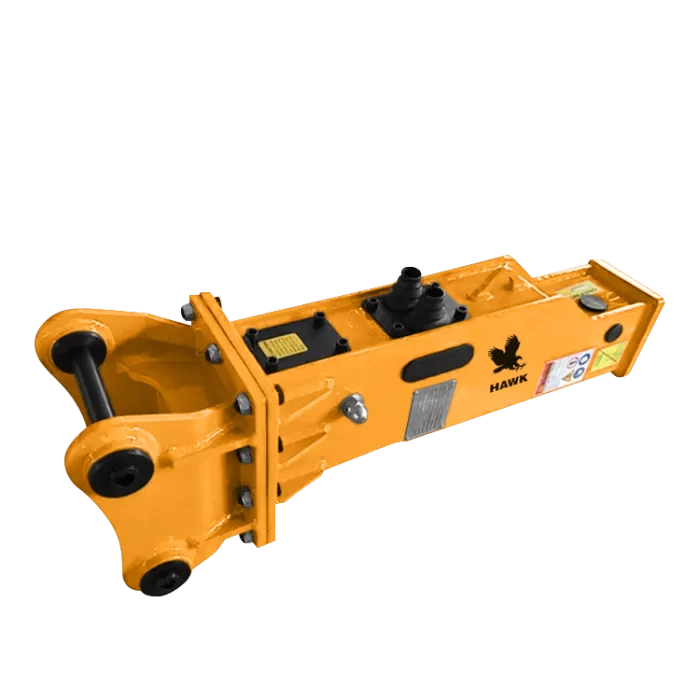

The HAWK HBH1650T top hydraulic breaker hammer plays a crucial role in mining, demolitions, excavations, and quarry operations, effectively dislodging large boulders and concrete structures. Contractors widely favor HAWK Excavator hydraulic hammers due to their superior performance and widespread presence on construction sites. These hydraulic breaker hammers streamline tasks, reduce manual labor, conserve energy, and proficiently break down concrete, rocks, and other sturdy materials.

HAWK Excavator’s top breaker hammers offer versatility, efficiency, and reliability, catering to diverse construction requirements. They are adaptable to various tasks, ensuring optimal performance across different construction scenarios. Our range includes top hydraulic breaker hammers tailored to fit various excavator makes and models, enhancing operational flexibility. Featuring straightforward yet advanced technology, our breaker hammer designs facilitate easy installation and maintenance, complemented by premium service support. This ensures a dependable resource on-site, enhancing productivity for routine construction activities.

The HAWK HBH1650T Hydraulic Breaker Hammer is a part of the comprehensive Top Hydraulic Breaker Hammer Series, which encompasses various diameters, tonnages, working flow, and working pressures, catering to diverse operational needs.

Benefits of Top Hydraulic Breaker Hammers

HBH1650T top hydraulic breaker hammers offer numerous advantages for construction, demolition, and mining applications:

Enhanced Productivity: Hydraulic breaker hammers deliver potent impacts, enabling efficient material breaking, thus reducing task completion time and effort.

Exceptional Versatility: These hammers are adaptable to various applications like demolition, excavation, trenching, and handling oversized materials. They can be mounted on diverse carriers such as excavators, backhoes, and skid steer loaders, providing operational flexibility.

Minimal Maintenance: Designed with few moving parts, top hydraulic breaker hammers mitigate the risk of mechanical failures and the need for frequent maintenance. The integrated hydraulic system also eliminates the requirement for a separate compressor or hoses, simplifying setup procedures.

Noise Reduction: HAWK Excavator Hydraulic breaker hammers emit lower noise levels than pneumatic or mechanical counterparts, making them suitable for urban environments or noise-sensitive areas.

Vibration Control: Incorporating advanced vibration control systems, hydraulic breaker hammers minimize transmitted vibration to carriers and operators, reducing fatigue and enhancing operator comfort, thus boosting productivity.

Robust Durability: Constructed with durable materials and components, these hydraulic breaker hammers are durable, ensuring prolonged service life even in challenging working conditions.

Energy Efficiency: Leveraging the hydraulic power of carriers, hydraulic breaker hammers demonstrate higher energy efficiency than pneumatic or mechanical systems, resulting in reduced fuel consumption and emissions.

Easy Attachment: Hydraulic breaker hammers can be swiftly attached to and detached from carriers, facilitating convenient switching between tools and tasks.

Features of Top Hydraulic Breaker Hammers

The HBH1650T top hydraulic breaker hammer is equipped with a range of features designed to optimize its performance, durability, and user-friendliness. These features include:

High-Impact Energy: HAWK Excavator’s top hydraulic breaker hammers are engineered to deliver formidable impacts, facilitating the efficient penetration of tough materials such as rock, concrete, and asphalt.

Advanced Vibration Control: Incorporating vibration-dampening systems, the HAWK breakers minimize the transmission of vibrations to both the carrier and the operator. This serves to mitigate operator fatigue, enhance comfort, and elevate productivity levels.

Robust Construction: Crafted from premium-quality materials and components, our hydraulic breaker hammers boast sturdy construction, enabling them to withstand demanding operational environments and ensuring an extended service life.

Variable Frequency and Energy Control: Operators can adjust the impact frequency and energy settings of the breaker, allowing for customization of its performance to suit different materials and applications.

Noise Reduction: HAWK Excavator’s top hydraulic breakers are engineered to reduce noise levels during operation, rendering them suitable for deployment in urban areas or environments sensitive to noise pollution.

Reviews

There are no reviews yet.