Description

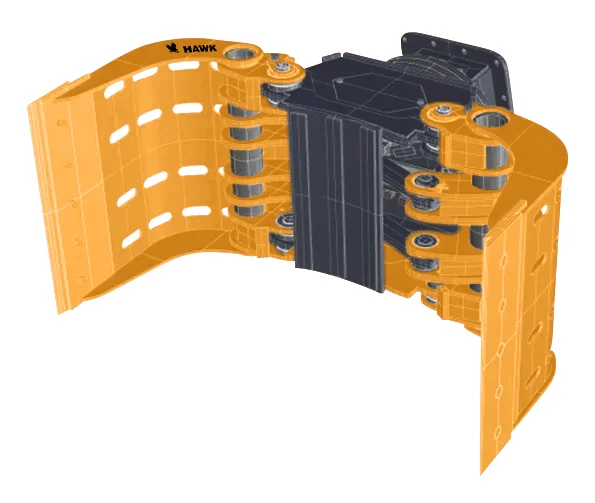

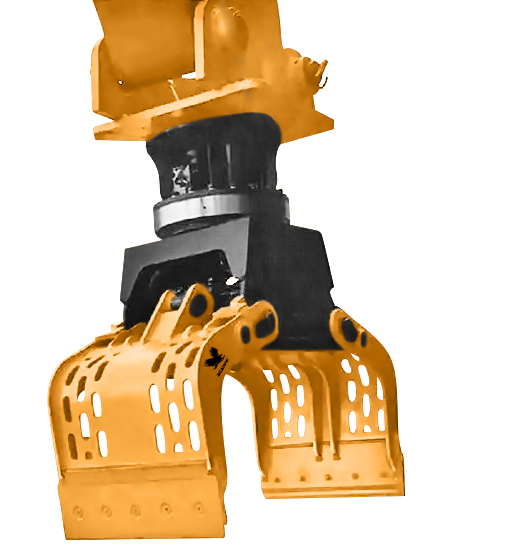

Hawk Excavator Grapples represent a versatile class of attachments engineered to optimize excavator functionality and operational efficiency across diverse industries and applications. Our product range encompasses four primary grapple types: mechanical, hydraulic, demolition, and rotary hydraulic, each meticulously designed to address specific tasks and operating conditions.

Characterized by precision engineering, premium materials, and innovative design, Hawk Excavator grapples deliver unparalleled performance, durability, and reliability even in the most challenging work environments. Our commitment to excellence ensures that operators are equipped with robust tools capable of efficiently and effectively handling tough jobs.

Opt for Hawk Excavator grapples to harness unmatched strength, versatility, and productivity on the job site, empowering operators to tackle a wide array of tasks with confidence and precision.

Key Specifications:

- Excavator Tonnage: 1-40 Ton

- Grapple Types: Mechanical, Hydraulic, Demolition, Rotary Hydraulic

- Mounting Options: Top, Side, Box (Noise Reducer)

- Chisel Options: Moil point, Blunt, Flat chisel, Conical point

- Applications: Concrete and rock fragmentation, handling of hard materials

Features of Box Hydraulic Breaker Hammers

At Hawk Excavator, our grapples are meticulously engineered to endure the exacting requirements of the construction, forestry, demolition, and waste management sectors. Here are the salient features of our excavator grapples:

Heavy-Duty Construction: Fabricated from robust materials like hardened steel, our grapples boast resilience to withstand the harshest operational environments. Reinforced welds and structural elements ensure enduring durability and dependability.

Versatile Design: Offering a spectrum of grapple types, including mechanical, hydraulic, demolition, and rotary hydraulic variants, our portfolio delivers adaptability to tackle diverse material handling duties. Whether for loading, sorting, lifting, or demolition tasks, our grapples are engineered to excel across various applications.

Adjustable Gripping Force: Hydraulic grapples are outfitted with adjustable gripping force capabilities, empowering operators to regulate material pressure for precise manipulation. This attribute enhances operational versatility and efficacy, particularly when handling delicate or irregularly shaped objects.

360-Degree Rotation (Rotary Hydraulic Grapples): Rotary hydraulic grapples feature a rotating mechanism facilitating full 360-degree rotation. This enables operators to effortlessly position and maneuver loads, obviating the need for frequent excavator repositioning.

Easy Installation and Compatibility: Engineered for swift and straightforward installation, our grapples minimize downtime while maximizing job site productivity. They seamlessly integrate with a broad array of excavator models, ensuring compatibility and convenience for operators.

Enhanced Productivity: Boasting superior gripping force, precise control, and versatile functionality, our grapples elevate job site productivity and efficiency. Whether managing bulk materials, debris, or demolition waste, our grapples empower operators to swiftly and effectively complete tasks.

Durable Wear Components: Our grapple designs incorporate wear-resistant elements such as replaceable teeth and cutting edges to withstand the abrasive impact of continuous usage in rugged environments. This guarantees sustained reliability and performance over the long term.

Safety Features: Safety remains paramount in heavy equipment operations. Equipped with safety enhancements like hydraulic pressure relief valves and reinforced structures, our grapples prioritize accident prevention and operator safety during operation.

Reviews

There are no reviews yet.