Hydraulic systems are widely used in equipment where power must be transferred efficiently and precisely. An HPU is the heart of any hydraulic system, converting mechanical power into hydraulic energy. Whether you’re dealing with heavy-duty construction equipment, a precision manufacturing machine, or any other industrial system, an HPU plays a pivotal role in determining the machine’s overall efficiency and performance.

When selecting the right HPU, two primary factors stand out: the power source and the specific requirements of your hydraulic system. The two most common types of HPUs are diesel hydraulic power units and electric hydraulic power units. Each has its own set of benefits and drawbacks, which will be explored in detail. Choosing between a diesel HPU and an electric HPU can affect your operational costs, environmental impact, and even the reliability of your equipment.

In this article, we will cover the key considerations for selecting the right HPU for your equipment, ensuring you have all the information needed to make the best choice for your needs.

Understanding Hydraulic Power Units

Before discussing how to select the right HPU, it’s important to understand what an HPU is and how it operates in a hydraulic system.

What is a Hydraulic Power Unit?

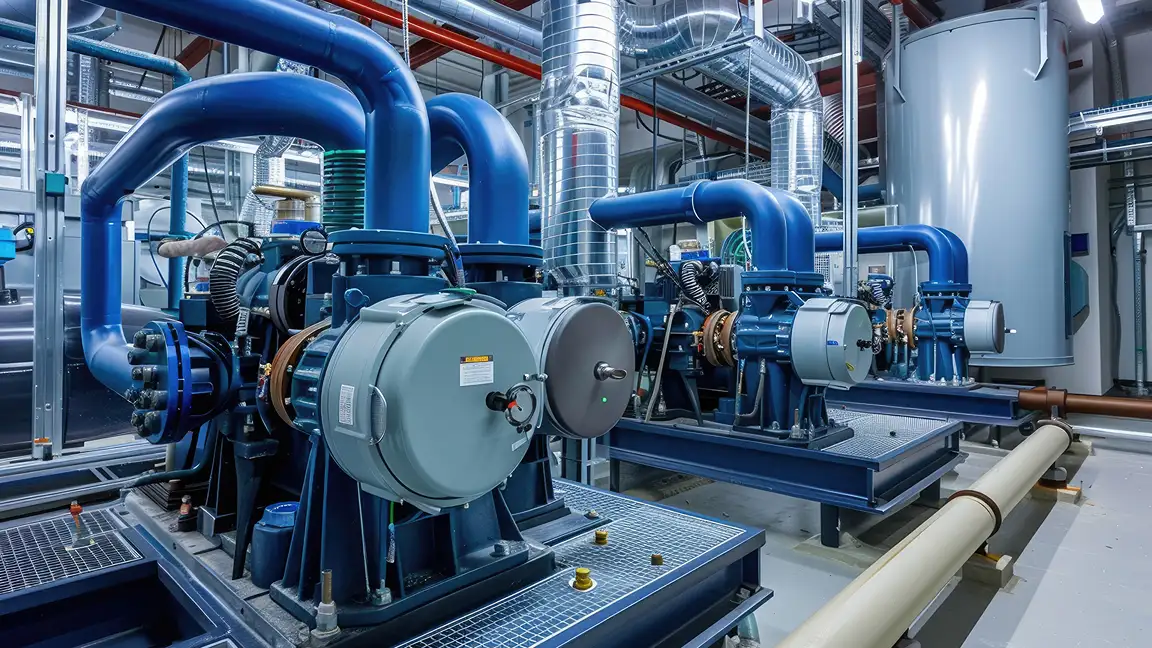

An HPU is a device designed to provide the pressure and flow required to power a hydraulic system. It plays a crucial role in converting mechanical energy into hydraulic energy, which then drives hydraulic machinery. This allows for efficient movement, lifting, pressing, and other mechanical operations in industries such as construction, manufacturing, agriculture, and more.

An HPU consists of several key components, each of which serves a specific function:

- Pump: The pump is the heart of the HPU. It draws fluid from the reservoir and pressurizes it to the desired levels. The pressurized fluid is then sent to the hydraulic system, which provides the force needed to operate the machinery. Depending on the application, the pump can be driven by either an electric hydraulic power unit or a diesel hydraulic power unit.

- Motor: The motor powers the pump, providing the mechanical energy necessary for the pump’s operation. Motors can be powered either electrically or by a diesel engine. The choice of motor type significantly impacts the overall performance, energy efficiency, and suitability for specific applications.

- Reservoir: This is the fluid storage tank, where hydraulic oil or fluid is kept. The size of the reservoir is critical, as it dictates how much hydraulic fluid is available to the system. A larger reservoir can accommodate longer operational hours without needing a refill, while a smaller one is typically used for more compact or mobile equipment.

- Control Valve: The control valve plays a pivotal role in regulating the direction and pressure of the hydraulic fluid. By adjusting these parameters, the control valve ensures the machinery operates efficiently and as required. It is key to providing the precise control needed for complex hydraulic movements.

- Filters: Clean hydraulic fluid is essential for the system’s longevity and reliability. Filters help remove contaminants that could damage the system’s internal components, ensuring the fluid remains clean and effective.

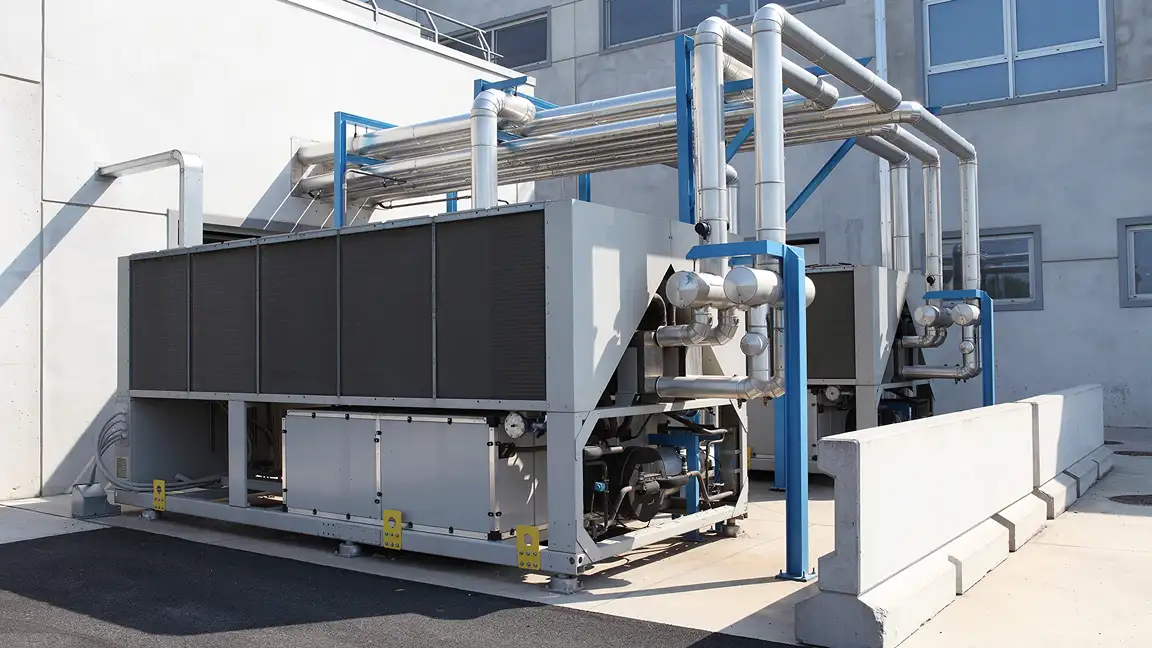

- Cooler (Optional): In larger systems or those with high heat generation, a cooler regulates the temperature of the hydraulic fluid. Keeping the fluid at an optimal temperature helps prevent overheating, which could decrease performance or prematurely wear the equipment.

Together, these components work seamlessly to provide reliable power to hydraulic systems. They are essential in a wide variety of applications, from lifting heavy loads in construction equipment to driving precision movements in manufacturing machinery. Whether using both the HPU is crucial for achieving optimal performance and efficiency in hydraulic operations.

In essence, the HPU serves as the backbone of any hydraulic system, ensuring that the equipment receives the necessary power to operate smoothly and efficiently. By understanding how these units work and their key components, you can make a more informed decision when selecting the right HPU for your equipment.

How Do HPUs Work?

The working principle of an HPU is fairly straightforward: a motor, either electric or diesel-powered, drives the pump that pressurizes the hydraulic fluid. This pressurized fluid is then sent through the hydraulic system to perform work—whether lifting a load, powering a mechanical arm, or actuating any other type of machinery.

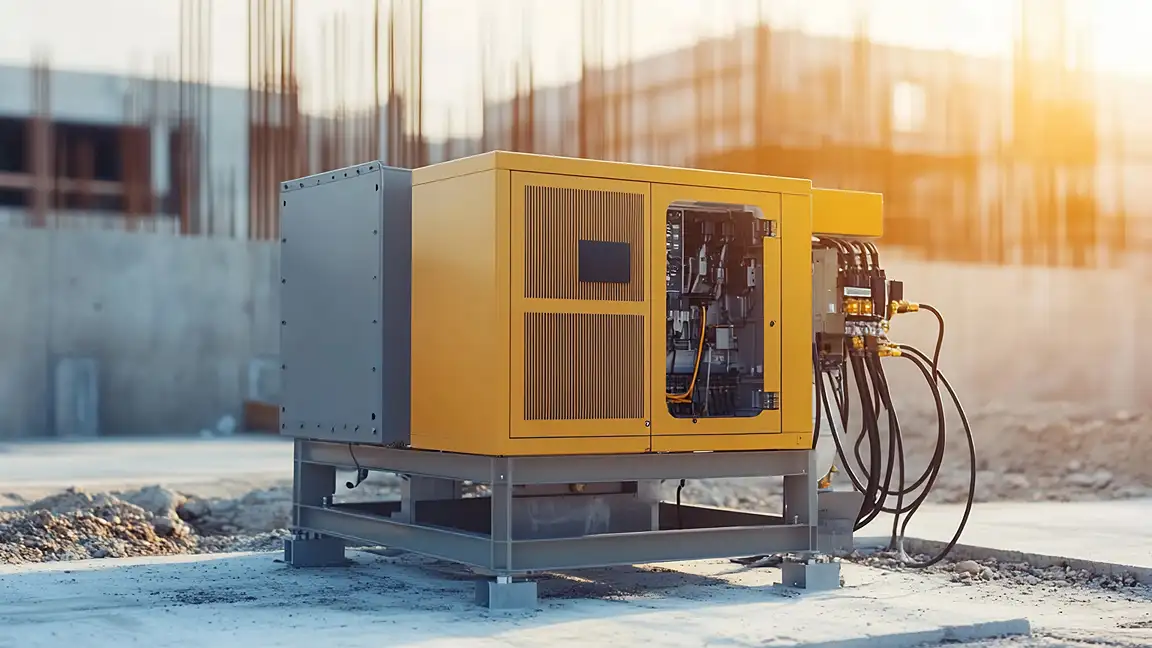

In a diesel-hydraulic power unit (HPU), the engine drives the pump to generate the necessary pressure to move hydraulic fluid through the system. This type of HPU is often used in heavy-duty applications where high power output and mobility are essential, such as construction or mining equipment.

On the other hand, an electric hydraulic power unit uses an electric motor to drive the pump. This type of HPU is ideal for environments with a stable power supply and a focus on efficiency and lower operational costs. It’s commonly found in manufacturing settings or industries that require quieter operation and cleaner energy sources.

Hydraulic power is highly efficient, making it ideal for systems requiring high force in a compact form. The fluid’s pressure can be easily adjusted to meet specific demands, and the system can quickly adapt to different workloads. Whether you’re using a diesel hydraulic power unit for heavy lifting or an electric hydraulic power unit for precise movements, both types offer unique advantages that enhance the performance and versatility of hydraulic systems.

Key Factors to Consider When Selecting an HPU

To ensure optimal performance, selecting the right HPU requires careful consideration of several key factors. Let’s examine these factors in more detail.

1. Pressure Requirements

Pressure is one of the most important factors to consider when selecting an HPU. Hydraulic systems rely on high pressure to transmit power, and the HPU’s pressure rating should match the needs of your equipment.

- Matching Pressure Ratings: The first step in choosing an HPU is understanding your system’s pressure requirements. Too little pressure will result in inadequate performance, while too much pressure can damage your hydraulic components. Always choose an HPU with a pressure rating that aligns with the maximum pressure needed by your equipment.

- Pressure vs. Flow: It’s important to note that pressure and flow are inversely related in a hydraulic system. High pressure generally means lower flow, while higher flow demands lower pressure. Understanding the pressure and flow requirements of your equipment will help you choose the right HPU.

2. Flow Rate

The flow rate of the hydraulic fluid plays a crucial role in determining the speed at which the equipment can perform its tasks. A higher flow rate means that the hydraulic system can operate faster, but it also requires a more powerful pump. Similarly, if the flow rate is too low for the equipment’s requirements, it could lead to slower operation or inadequate performance.

- Determining Flow Needs: To calculate the ideal flow rate, consider the machinery’s operation speed and the size of the cylinders or actuators used. Equipment that needs to move heavy loads or perform high-speed actions will typically require a higher flow rate.

3. Size and Capacity

The size and capacity of the HPU must match the hydraulic system’s requirements. A too-small unit might struggle to meet the power demands of larger or more demanding equipment, while an oversized unit could lead to unnecessary energy consumption and higher costs.

- Choosing the Right Size: Consider your equipment’s power needs and the available space where the HPU will be installed. HPUs come in various sizes, so selecting one that is appropriately sized for the system’s operational needs is essential for long-term efficiency.

4. Power Source: Diesel vs. Electric HPUs

When it comes to power sources, the two main types of HPUs are diesel-powered and electric-powered. Both types have distinct advantages and disadvantages, and the choice depends on your equipment’s specific needs.

Diesel Hydraulic Power Units

- Pros:

- Ideal for remote locations where electricity is not readily available.

- Generally offers higher power output for large-scale operations.

- Diesel engines have higher efficiency in heavy-duty applications.

- Cons:

- Diesel-powered HPUs produce emissions, which may be a concern for environments with strict environmental regulations.

- They can be noisy and require regular maintenance, including fuel management and oil changes.

- Typically have higher operational costs due to fuel consumption.

Electric Hydraulic Power Units

- Pros:

- Lower environmental impact due to no emissions.

- Quieter operation, making them suitable for environments where noise reduction is important.

- Lower operating costs, as electricity is generally cheaper than diesel fuel in many regions.

- Cons:

- May not be suitable for remote areas where electrical power is unavailable.

- Typically not as powerful as diesel units, which can be a limitation for heavy-duty equipment.

- Requires a stable power supply, which may be disrupted in certain environments.

5. Compatibility and Integration

Ensuring that the HPU is compatible with your existing equipment is crucial for smooth operation. Compatibility factors include:

- Mounting: The HPU must fit into the available space on your equipment. If your equipment has specific mounting requirements, you need to ensure that the both power unit can be securely installed, without disrupting the flow or access to other components.

- Hoses and Valves: The connections and fittings for hoses and valves must be compatible with the HPU’s output. Compatibility between components is essential to prevent leaks, ensure efficient fluid transfer, and maintain seamless hydraulic operation.

- System Integration: If your equipment is part of a larger system, the HPU must integrate well with other components, such as control systems, sensors, and feedback mechanisms. Whether you are using a diesel-hydraulic power unit for remote work environments or an electric hydraulic power unit for more controlled operations, the system must communicate and work together seamlessly to ensure optimal performance.

Maintenance and Longevity

whether a diesel hydraulic power unit or an electric hydraulic power unit, requires routine maintenance to ensure optimal performance and extend their lifespan. Regular maintenance includes:

- Fluid Changes: The hydraulic fluid should be checked and replaced at regular intervals to ensure cleanliness and prevent contamination. This is particularly important in diesel hydraulic power units, where fluid breakdown due to high temperatures may require more frequent attention.

- Filter Replacement: Hydraulic filters should be replaced or cleaned periodically to prevent dirt and debris from damaging the system. Both electric and diesel hydraulic power units depend on clean fluid for efficient operation, so regular filter maintenance is key.

- System Inspection: Regular inspections of the pump, motor, and other components will help identify any wear or potential failures before they become critical. For electric hydraulic power units, this means checking electrical components and wiring, while diesel hydraulic power units require additional checks for engine performance and fuel efficiency.

Proper maintenance will minimize downtime, extend the life of your equipment, and reduce the likelihood of costly repairs, regardless of whether you’re using a diesel hydraulic power units or an electric hydraulic power unit.

Making the Final Decision

Choosing the right HPU requires weighing various factors. Here are some key points to consider:

- Work Type and Environment: Is your equipment used in a high-demand, heavy-duty environment? If so, you might need a more powerful diesel-powered HPU. For lighter tasks or indoor applications, an electric-powered unit may be more suitable.

- Power Source Preferences: Do you need the flexibility to use the equipment in remote locations? Diesel hydraulic power units are ideal for these situations. However, if environmental concerns or cost efficiency are more critical, an electric HPU could be the better choice.

- Cost vs. Benefit: While diesel-powered HPUs may have a higher upfront cost and operating expenses, they may offer superior power and durability for heavy-duty applications. Electric HPUs may be more cost-effective and environmentally friendly in the long run.

Conclusion

Choosing the right HPU for your equipment requires careful consideration of several key factors, including pressure requirements, flow rates, power source, and compatibility with existing systems. Whether you choose a diesel or electric hydraulic power unit will depend on the specific demands of your equipment, your work environment, and your operational goals.

By understanding the nuances of each option and considering your long-term operational needs, you can make an informed decision that will ensure your hydraulic systems perform at their best for years to come. The right HPU boosts equipment efficiency and reduces downtime and operating costs.

Post a Comment