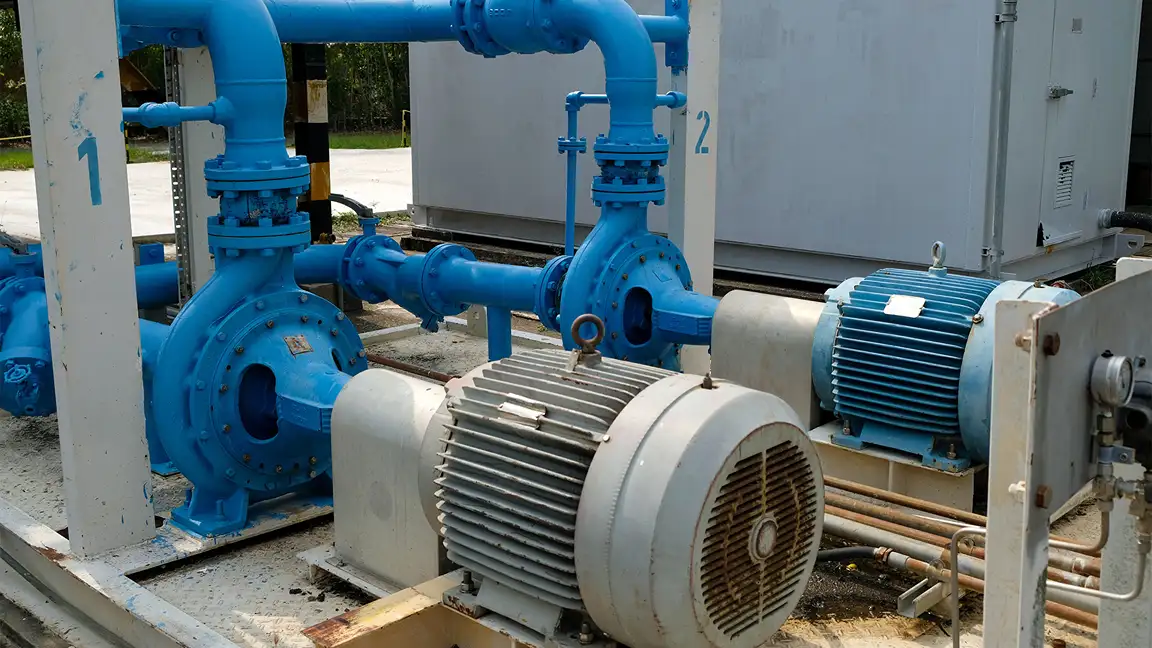

Water pumps transfer water from one location to another, and they are vital in a variety of commercial applications. Depending on the type, pumps are used for irrigation, drainage, water treatment, heating systems, and more. Factors such as the water source, intended use, operation size, and location determine the right pump for your business.

Commercial water pumps are specifically designed for larger-scale operations. They provide higher flow rates, enhanced durability, and improved energy efficiency compared to residential models. These pumps are built to handle larger water volumes and more demanding conditions, making them ideal for a wide range of commercial needs.

In particular, commercial well pumps are essential for businesses that depend on deep water sources, extracting water from underground wells. For operations requiring a constant and reliable water supply from wells, selecting the right commercial well pump is crucial for efficient and sustainable water management.

Understanding the different types of commercial water pumps, including commercial well pumps, and their applications can ensure that your water system operates efficiently. In this guide, we’ll highlight the key factors to consider when purchasing a commercial water pump, including aspects of commercial pumping systems, to ensure that your business’s water management needs are met effectively. Commercial pumping solutions play a significant role in achieving these goals, providing reliability and efficiency for your business.

Why Choosing the Right Pump Matters

Selecting the right commercial water pump is crucial for the efficiency and cost-effectiveness of your operations. A poor choice can result in negative outcomes, such as increased downtime, higher energy consumption, and frequent maintenance. This is especially critical for businesses that rely on commercial well pumps, as the proper selection directly impacts the ability to extract water from deep underground sources efficiently.

If the flow rate of the pump is too low to meet your business’s water demand, the commercial pumping system will struggle to maintain the necessary supply, leading to higher energy consumption and potential breakdowns. Conversely, an overpowered pump, such as a commercial well pump with a flow rate that exceeds the required capacity, can waste energy, increase initial costs, and raise operational expenses unnecessarily.

Additionally, selecting the right pump is essential for meeting local environmental regulations. Many regions require pumps to meet specific standards that minimize their environmental impact. By choosing the correct commercial water pump or commercial well pump, you improve operational efficiency and ensure compliance with environmental and safety regulations, helping you avoid potential fines and disruptions to your business. Ultimately, the right pump ensures your commercial pumping systems operate smoothly, reducing risks and optimizing productivity.

Types of Commercial Water Pumps

Choosing the right type of commercial water pump is crucial for efficient water management in your business. Different pumps are designed for specific applications, and selecting the most appropriate one ensures optimal performance. Below are some of the most common types of commercial water pumps:

Centrifugal Pumps

Centrifugal pumps are widely used in commercial water systems across various industries. These pumps operate by utilizing centrifugal force to move water. As the water enters the center of a rotating impeller, it is pushed outward into the discharge pipe, creating a continuous flow.

Advantages of Centrifugal Pumps:

- High Flow Rates: Centrifugal pumps are highly efficient in handling large volumes of water, making them ideal for applications that require high capacity.

- Energy Efficiency: These pumps are cost-effective, particularly in low to medium-pressure applications, helping businesses reduce operational costs.

- Versatility: They are incredibly versatile and are commonly used in a wide range of applications, including water treatment, HVAC systems, irrigation, fire protection, and more.

Common Applications:

Centrifugal pumps are widely employed in municipal water distribution, commercial well pumps, commercial buildings, irrigation systems, and fire protection. Due to their reliability and efficiency, they are a popular choice for commercial pumping needs, ensuring steady and continuous water flow in large-scale operations. Whether moving water in a commercial well or supporting municipal systems, centrifugal pumps offer excellent performance across diverse sectors.

Positive Displacement Pumps

Positive displacement pumps work by trapping a fixed volume of water and forcing it through the discharge pipe. These pumps are ideal for applications requiring constant flow and high pressure, such as commercial well pumps.

Advantages of Positive Displacement Pumps:

- Constant Flow: Ensures steady, consistent water flow.

- High Pressure: Suitable for high-pressure applications like commercial well pumps.

- Precise Flow Control: Essential for accurate water delivery in industries like chemical processing and oil and gas.

Common Applications:

- Chemical processing, oil and gas, and commercial pumping systems.

Diaphragm Pumps

Diaphragm pumps use a flexible diaphragm to create suction, ensuring consistent water flow even under fluctuating pressures.

Advantages of Diaphragm Pumps:

- Self-Priming: Can be used without manual priming, ideal for deep or hard-to-reach water sources.

- Handling Suspended Solids: Capable of pumping water with debris or contaminants.

- Durability: Requires less maintenance due to fewer moving parts.

Common Applications:

- Wastewater treatment, chemical handling, and industrial operations.

Submersible Pumps

Submersible pumps are designed to be submerged directly in the water they pump. These pumps are particularly effective for deep water sources, such as commercial water pumps used in commercial well applications.

Advantages of Submersible Pumps:

- Efficiency at Depth: Perfect for deep-well applications, efficiently pumping water from significant depths.

- Compact Design: Ideal for installations where space is limited.

- Quiet Operation: Well-suited for noise-sensitive environments.

Common Applications:

Submersible pumps are commonly used in deep wells, sewage systems, flood control, and industrial dewatering.

Other Types of Commercial Water Pumps

Specialized pumps like jet pumps, screw pumps, and peristaltic pumps are designed to meet the unique needs of various industries. These pumps play a crucial role in ensuring efficient commercial pumping operations.

- Jet Pumps: Typically used in shallow wells, jet pumps are ideal for low-demand applications where water sources are near the surface. They provide reliable performance in commercial pumping systems that require modest water flow.

- Screw Pumps: Designed to handle high-viscosity fluids or slurries, screw pumps are commonly used in agriculture and industry. They are particularly effective for moving thick, heavy liquids in commercial pumping applications.

- Peristaltic Pumps: Known for their precise control, peristaltic pumps are ideal for industries such as pharmaceuticals, food processing, and chemicals, where fluid handling accuracy is essential.

For businesses that rely on commercial well pumps, selecting the right type of pump for their specific needs ensures smooth operation and optimal efficiency in their water management systems.

Key Factors to Consider When Choosing a Commercial Water Pump

When selecting a commercial water pump, several factors need to be considered. Below are some of the most important elements to evaluate:

Flow Rate and Capacity

The flow rate of a pump determines how much water can be moved in a set amount of time. It is usually measured in gallons per minute (GPM) or liters per second (L/s). Knowing your water usage needs is important for selecting the right pump.

Considerations for Flow Rate:

- Peak Demand: Calculate your business’s highest water demand. This is typically during peak operation hours or seasonal changes (e.g., summer for agricultural businesses).

- System Size: The diameter of your pipes and the number of fixtures or devices drawing water from the system will impact the flow rate needed.

Pressure Requirements

Pressure refers to the force needed to move water through the system. Pumping water to great heights requires higher pressure. Similarly, the length and diameter of pipes influence pressure requirements, as longer and narrower pipes require higher pressure to move water.

Considerations for Pressure:

- Water Source Depth: Deeper wells or reservoirs require higher pressure to draw water to the surface.

- Friction Losses: The longer the pipe system, the higher the frictional loss, which impacts the pressure needed.

Power Source

Water pumps can be powered by electricity, diesel, or solar energy. The power source chosen should align with your operations and the availability of resources at your location.

- Electric-Powered Pumps: Most commercial water pumps are electric, making them ideal for businesses with access to a reliable electrical grid.

- Diesel-Powered Pumps: Diesel pumps are suited for areas without access to electricity or where portability is needed.

- Solar-Powered Pumps: Solar-powered pumps are becoming increasingly popular for businesses looking to reduce their carbon footprint and lower energy costs.

Pump Durability and Material

The durability of a commercial water pump depends on the materials it’s made from. Common materials include:

- Stainless Steel: Corrosion-resistant and ideal for harsh environments, ensuring long-lasting performance.

- Cast Iron: Durable but prone to rust over time, making it suitable for environments where corrosion isn’t a major concern.

- Thermoplastic: Lightweight and corrosion-resistant but less durable than metal-based pumps.

Energy Efficiency and Cost-Effectiveness

A commercial water pump designed for energy efficiency can significantly reduce operational costs. Look for models with high energy ratings or variable speed drives (VSDs), which adapt to performance demands and optimize energy usage. Investing in energy-efficient commercial water pumps not only helps lower energy consumption but also reduces long-term expenses.

Maintenance and Serviceability

Regular maintenance is key to ensuring the longevity of your commercial water pump. Consider the following for optimal performance:

- Low-Maintenance Pumps: Diaphragm and centrifugal pumps, with fewer moving parts, generally require less maintenance and are easy to use over time.

- Spare Parts Availability: To minimize downtime and ensure continuous operation, make sure that replacement parts for your commercial water pump are readily accessible, especially in remote areas.

Selecting the right commercial well pump is essential for businesses that need to extract water from deep underground. Whether you are looking to optimize your commercial pumping system or ensure long-term performance, the right pump will help improve efficiency, reduce operational costs, and maintain productivity.

Commercial Well Pumps: What Makes Them Special?

Commercial well pumps are designed to pump water from wells, which can vary in depth from a few feet to hundreds of feet. These pumps are essential for businesses that rely on underground water sources, such as agriculture, manufacturing, and municipal systems. The right commercial water pump ensures an efficient, reliable water supply from wells, enabling consistent operations and water availability.

Selecting the right pump depends on the well’s depth, water level, and required flow rate. Making the right choice minimizes energy consumption, prevents overuse, and ensures long-term performance. With the right commercial pumping system, businesses can maintain water flow and prevent costly operational disruptions.

Choosing the Right Well Pump

- Shallow Wells: For wells up to 25 feet deep, jet pumps or centrifugal pumps are ideal. These commercial water pumps can efficiently handle lower depths and provide sufficient water flow for businesses with moderate water needs, ensuring a reliable water supply.

- Deep Wells: Commercial well pumps, such as submersible pumps, are more suitable for deeper wells. These pumps are specifically designed to operate at greater depths, providing a steady flow of water. This makes them ideal for businesses in areas with significant water depth, ensuring that their water supply remains efficient and reliable, even in challenging conditions.

Maintenance of Commercial Well Pumps

Regular maintenance of your commercial water pump and commercial well pumps is crucial for ensuring optimal performance and avoiding costly repairs. Key maintenance tasks include:

- Sediment Build-Up: Sediment can accumulate over time and block water flow, reducing pump efficiency. Regular inspection and cleaning help prevent sediment buildup, ensuring a steady water supply and maintaining the effectiveness of your system.

- Mechanical Failures: Components like impellers and seals wear out with use, causing pump malfunctions. Routine inspections can identify these issues early, allowing for repairs before more significant damage or operational disruptions occur.

- Motor Malfunctions: It’s important to check the pump motor to ensure it operates efficiently and regularly. Preventing motor malfunctions through consistent maintenance not only extends the life of your commercial well pump but also reduces the likelihood of unexpected breakdowns and costly downtime.

By staying on top of these maintenance tasks, you can ensure your commercial water pump continues to run smoothly, maximizing efficiency and minimizing the risk of costly repairs or system failures.

Conclusion

Choosing the right commercial water pump is crucial for the efficiency, cost-effectiveness, and longevity of your water system. By understanding the various types of pumps, their features, and performance factors, you can make an informed decision that best meets your business’s needs. Key considerations such as flow rates, pressure requirements, energy efficiency, and reliability will ensure your system runs at its optimal performance.

For businesses relying on commercial well pumps, selecting the right pump is essential to minimize operational costs and boost long-term efficiency. With the appropriate commercial water pump in place, your business can maintain smooth operations, reducing downtime and preventing costly repairs.

Post a Comment