Hydraulic power units are used in many industrial systems to move, lift, and control heavy loads. They are found in manufacturing plants, mobile machinery, dredging equipment, and other demanding environments. For these systems to work properly, pressure and fluid flow must remain stable throughout operation.

Problems start when pressure drops or flow becomes uneven. Cavitation and pressure spikes often develop quietly inside hydraulic power units and damage components over time. If cavitation prevention and pressure spike control are not addressed early, the system may suffer from faster wear, unexpected downtime, and reduced performance. Understanding how these issues occur helps operators protect equipment and maintain reliable operation.

.

What Cavitation Really Means Inside Hydraulic Power Units

How Cavitation Forms

Cavitation happens when pressure inside a hydraulic power unit drops too low for the hydraulic fluid. When this pressure falls below the fluid’s vapor pressure, small vapor bubbles form in the oil. These bubbles are not visible and form inside the flowing fluid.

As the fluid moves into a higher-pressure area, the bubbles collapse suddenly. Each collapse releases a small but strong удар of energy against nearby metal surfaces. Over time, this repeated impact damages pump housings, wears down impeller edges, and erodes valve seats. As damage builds up, fluid flow becomes unstable, efficiency drops, and mechanical wear spreads through the system.

Where Cavitation Typically Begins

In most hydraulic power units, cavitation starts in areas where pressure is already low or where flow is restricted:

- Pump inlets and suction lines

- Low-pressure zones after sharp bends or flow restrictions

- High-speed flow areas caused by undersized hoses or fittings

- Locations where air is trapped or mixed into the fluid

These conditions are common in compact systems where space limits lead to long suction lines, tight bends, or pumps placed above the reservoir. If these areas are not addressed during design or operation, they become repeated cavitation points that slowly reduce system performance.

Why Cavitation and Pressure Spikes Happen Together

Cavitation and pressure spikes are closely linked inside hydraulic power units. They usually happen as part of the same instability, not as separate problems. When fluid flow becomes uneven or restricted, pressure drops in certain areas of the system. These low-pressure zones allow vapor bubbles to form.

When the system tries to recover, the same fluid is forced to slow down or change direction quickly. This sudden change creates sharp pressure spikes. The result is a repeating cycle where pressure drops form bubbles, and rapid pressure recovery collapses them with force. Over time, this cycle damages internal components and reduces system reliability.

Root Causes in Real Systems

Several common operating and design issues trigger both cavitation and pressure spikes:

- Restricted or undersized suction plumbing lowers inlet pressure and allows vapor bubbles to form

- Air entering through loose fittings or worn seals creates compressible pockets that worsen pressure swings

- Clogged strainers or collapsed hoses restrict flow and destabilize pump supply

- Cold starts increase fluid resistance and cause pump starvation before flow stabilizes

- Rapid valve closure or sudden direction changes force fluid to stop too quickly, creating pressure spikes

Each of these issues either pulls pressure below safe limits or forces fluid to decelerate too fast. In hydraulic power units, this turns normal operation into repeated stress events that shorten component life.

Early Warning Signs Most Teams Miss

Cavitation and pressure instability rarely manifest as sudden breakdowns. In most hydraulic power units, the damage begins quietly, manifesting as subtle performance changes that are easy to dismiss in day-to-day operation. These early indicators reflect fluid instability and internal stress long before visible component failure occurs.

Common indicators:

- Rattling or gravel-like noise from the pump during operation

- Vibration transmitted through piping, manifolds, or mounting frames

- Pressure gauge needles that fluctuate instead of holding steady

- Foamy or cloudy appearance in the hydraulic fluid

- Premature seal degradation or bearing wear

These symptoms often surface weeks or months before a pump seizes, a hose ruptures, or a valve fails. Recognizing them early allows teams to correct root causes while the system is still intact, preventing minor instability from escalating into catastrophic damage.

Designing Hydraulic Power Units for Cavitation Prevention

Cavitation prevention starts with how a hydraulic power unit is designed, not after problems appear. The physical layout of the system affects how easily fluid reaches the pump and how stable the pressure remains during operation. Good design reduces the chances of pressure dropping low enough for vapor bubbles to form.

Suction Side Geometry

The suction side of the system plays a major role in protecting the pump from cavitation. Poor suction design makes the pump work harder to pull fluid, increasing the risk of pressure collapse.

Key practices include:

- Keep suction lines as short and straight as possible

- Avoid vertical lifts that reduce inlet pressure

- Remove unnecessary elbows, reducers, and fittings

- Use larger hose sizes to reduce fluid speed and pressure drop

These steps help maintain steady inlet pressure and a continuous flow of fluid, both of which are critical for preventing cavitation in hydraulic power units.

Reservoir Behavior

The reservoir also helps control pressure stability. A properly sized tank allows the fluid to slow down, release trapped air, and stabilize temperature before returning to the pump. Baffles inside the reservoir reduce turbulence and prevent return flow from moving directly into the suction area.

By keeping return flow away from the pump inlet, the reservoir limits aeration and helps deliver a calm, steady fluid supply. This stable supply supports cavitation prevention by reducing pressure fluctuations at the pump inlet.

Controlling Pressure Spikes at the System Level

Pressure spikes in hydraulic power units occur when moving fluid is forced to slow down or change direction too quickly. Fluid in motion carries energy, and when that motion is stopped suddenly, the energy turns into a sharp rise in pressure. These spikes happen very fast and can exceed system limits before operators notice.

Over time, repeated pressure spikes damage hoses, stress fittings, and reduce the life of pumps, valves, and seals. Controlling these spikes helps protect the entire system from long-term fatigue.

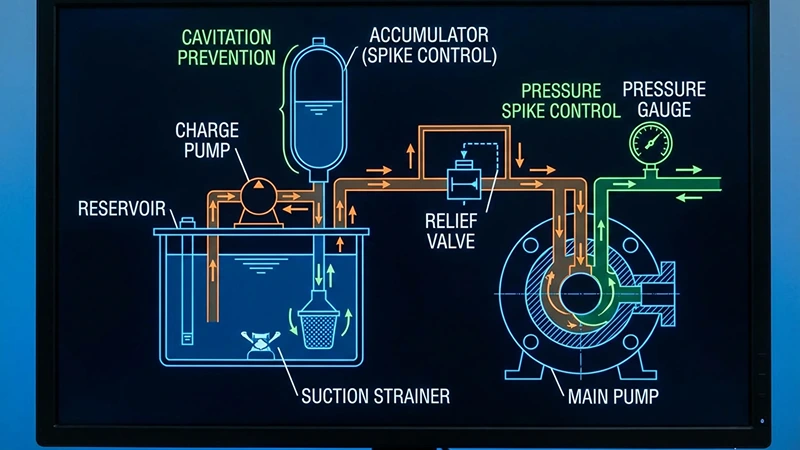

Accumulators and Dampening Devices

Accumulators and dampeners absorb sudden pressure changes inside the system. They provide a small, compressible space that takes in excess energy during a pressure spike and releases it gradually.

This reduces shock loads on pumps and valves, keeps pressure more stable during load changes, and prevents repeated spikes from weakening components over time.

Valve Dynamics

Valve operation has a direct impact on pressure behavior. Valves that close too fast or change direction suddenly cause instant flow interruption. This leads to sharp pressure spikes, even during normal operation.

Using valves with smoother spool movement, balanced designs, and proper sequencing allows fluid to slow down instead of stopping abruptly. This turns sudden shock into controlled pressure change.

Control Logic Techniques

- Ramped starts and stops to avoid sudden flow acceleration

- Staged directional changes between movements

- Flow control on return lines to manage deceleration energy

- Built-in deceleration zones in motion circuits

These methods shift pressure management from reaction to control, helping hydraulic power units operate smoothly under changing loads.

Operational Practices That Protect Hydraulic Power Units

Daily operation has a direct impact on how long a hydraulic power unit remains stable and reliable. Even a well-designed system can wear out early if it is operated in a way that causes repeated pressure drops, temperature stress, or sudden shock loading. Simple operating habits help keep fluid behavior predictable and reduce internal stress.

Fluid Selection and Temperature Control

Hydraulic fluid must flow easily into the pump to maintain stable pressure. When fluid is too thick, especially during cold starts, resistance on the suction side increases. This lowers inlet pressure and raises the risk of vapor formation.

Starting the system under full load with cold oil forces the pump to pull harder than the fluid can respond. A proper warm-up routine allows oil to circulate at low load, reduces viscosity, stabilizes inlet pressure, and removes trapped air before full operation begins.

Pump Matching and Load Behavior

Pumps perform best when they operate within their normal working range. Oversized pumps running under light load or undersized pumps pushed too hard both create unstable conditions.

Matching pump capacity to actual system demand helps maintain steady inlet pressure and avoids rapid changes between starved and overloaded states.

Duty Cycle Awareness

- Avoid running at continuous peak flow

- Limit rapid cycling under heavy load

- Stagger demand when multiple actuators are used

These practices reduce repeated pressure drop and recovery cycles, allowing hydraulic power units to operate within safe and controlled limits.

Preventive Maintenance as a Stability Tool

Preventive maintenance in hydraulic power units does more than keep equipment clean. It directly affects pressure stability and fluid behavior. Small issues like restrictions, air leaks, or sensor drift slowly change how fluid moves through the system. If left unchecked, these problems create unstable suction conditions and sudden pressure changes.

When maintenance is done with intent, it helps keep fluid paths clear and pressure feedback accurate. This prevents small issues from building into cavitation and pressure spike problems.

Checklist:

- Inspect suction strainers on a regular schedule

- Check hoses for damage, collapse, or poor routing

- Monitor hydraulic fluid level and clarity

- Calibrate pressure sensors and gauges

- Make sure breathers are clean and functioning

Each of these steps helps prevent hidden pressure loss and air entry. Consistent maintenance keeps inlet conditions stable, reduces pressure fluctuation, and lowers the risk of cavitation throughout the life of hydraulic power units.

Monitoring and Diagnostics for Early Intervention

Modern hydraulic power units do not have to operate without feedback. Monitoring systems allow operators to see pressure, temperature, and flow behavior as it changes, instead of finding problems after parts fail. This makes cavitation prevention and pressure spike control easier to manage and correct early.

By tracking system behavior over time, small issues can be identified before they cause serious damage.

What to Measure

- Inlet pressure to ensure the pump is not starved

- System pressure ripple to detect shock and oscillation

- Temperature rise rate to identify restriction or overload

- Flow stability to reveal air entry or internal leakage

Turning Data Into Action

Single readings are less useful than trends. A slow drop in inlet pressure, increasing pressure fluctuations, or faster-than-normal temperature rise usually points to developing instability.

Acting on these patterns early allows teams to correct the root cause while the system is still intact. This prevents vapor formation, reduces shock loading, and protects hydraulic power units from long-term damage.

Practical Takeaways for Cavitation Prevention and Pressure Spike Control

Cavitation and pressure spikes are not random problems inside hydraulic power units. They happen when fluid flow is unstable, suction conditions are poor, control actions are too sudden, or maintenance is neglected. These issues build over time and damage components from the inside.

Stable inlet pressure, smooth valve operation, proper fluid behavior, and regular monitoring work together to reduce risk. When system design, daily operation, and preventive care focus on fluid stability, cavitation prevention and pressure spike control become manageable rather than reactive.

For teams looking to improve the reliability of their hydraulic power units, working with experienced specialists can speed up results. At Pump Enterprise, we support system design, configuration, and maintenance to reduce cavitation and control pressure changes throughout system life. Whether upgrading existing equipment or building new systems, the right engineering approach turns unstable behavior into consistent performance.

Post a Comment