Submersible pumps are essential in mining, oil and gas, municipal water systems, and marine infrastructure, operating below fluid surfaces to handle water, wastewater, slurry, or industrial fluids in tough conditions. As a result, submersible pump manufacturers play a crucial role in maintaining uptime, reliability, and efficiency in these environments.

With rising energy costs and increasingly stringent regulations, there’s a growing demand for energy-efficient solutions. Leading submersible pump manufacturers are responding by developing smarter systems that reduce power use and improve output. Innovations such as digital diagnostics and smart monitoring are now commonplace among advanced submersible pump suppliers, enabling operators to boost performance and extend equipment life.

Today’s buyers, ranging from municipal agencies to offshore contractors, prioritize long-term ROI over just durability. Metrics such as lifecycle energy savings, total cost of ownership, and predictive maintenance now influence procurement.

To meet these needs, top manufacturers are advancing motor design, materials, and automation to solve both technical and economic challenges. In the following sections, we’ll explore how these innovations deliver real-world benefits, ranging from reduced energy use to enhanced operations across various sectors.

How Submersible Pump Manufacturers Are Enhancing Energy Efficiency

Designing for the Best Efficiency Point (BEP)

Submersible pump manufacturers enhance efficiency by engineering pumps to operate near their Best Efficiency Point (BEP), where hydraulic and mechanical forces are in balance. Optimized impeller geometry and casing design reduce wear, vibration, and energy waste. For industrial submersible pumps used in high-demand applications, such as desalination or slurry transfer, BEP-focused models ensure optimal flow performance and lower operating costs.

Integration of Variable Frequency Drives (VFDs)

VFDs allow real-time speed control, aligning power use with system demand. Submersible pump suppliers now offer VFD-compatible systems to replace inefficient throttling methods. These setups are especially valuable in sectors with fluctuating flow needs, such as municipal water or mining operations, helping industrial submersible pumps reduce both energy use and mechanical stress.

Reducing Pump Cycling and Energy Loss

Frequent starts and stops reduce efficiency and wear down components. To prevent this, submersible pump manufacturers develop control logic and hydraulic buffers to stabilize operations. Smart controllers from leading submersible pump suppliers detect demand patterns, reducing cycling and improving both energy efficiency and pump lifespan.

Improved Installation Guidelines

Efficiency extends beyond the pump itself. Manufacturers now provide detailed guidance on piping, bends, and flow alignment to reduce head loss. Proper installation ensures that industrial submersible pumps operate at peak efficiency, making system-wide optimization easier for operators.

Energy-Efficient Motors

New models from submersible pump manufacturers feature IE3 or higher-rated motors, which provide more efficient energy conversion from electrical to mechanical energy. These high-efficiency pumps are ideal for continuous-use sectors, such as oil and gas or irrigation, providing long-term energy savings.

ROI Through Energy Savings

Energy-efficient pumps offer tangible cost benefits, especially in power-intensive sectors. Submersible pump suppliers help clients assess long-term savings through benchmarking and simulations, making it easier to justify premium models with better lifecycle value and lower operational costs.

Smart Monitoring: The Digital Edge in Pump Management

IoT and Sensor Integration

Submersible pump manufacturers are increasingly embedding smart sensors into their systems to enable real-time monitoring of flow, vibration, pressure, and temperature. This IoT integration supports a connected, intelligent infrastructure where pump behavior is tracked through centralized dashboards. Many manufacturers now offer this as standard, enhancing reliability and uptime in demanding environments.

Real-Time Performance Tracking

Modern submersible pump manufacturers focus on live data tracking to detect issues before failure occurs. Key performance indicators, such as discharge flow and power draw, are monitored in real-time. These insights are particularly valuable in sectors such as mining, wastewater treatment, and offshore oil and gas operations.

Predictive Maintenance

By applying AI and machine learning, these systems now offer predictive maintenance capabilities. Instead of relying on routine schedules, predictive tools forecast wear and enable targeted interventions. Manufacturers now bundle analytics tools with their systems to reduce downtime and extend the life of their equipment.

Remote Diagnostics and Alerts

For remote or hazardous locations, manufacturers offer secure cloud platforms for remote access and diagnostics. Alerts are triggered automatically when performance deviates from thresholds. Users can remotely configure responses, making them ideal for oilfields, military bases, or agricultural zones.

Cost Justification

To validate investment in smart systems, manufacturers provide ROI projections and case studies. These demonstrate how smart monitoring reduces OPEX by lowering energy consumption, reducing unplanned repairs, and extending service life. Calculators are often included to help teams quantify these savings.

Material and Motor Innovations Driving Efficiency Gains

Corrosion-Resistant Alloys and Polymeric Materials

Durability in corrosive and abrasive environments is crucial for maintaining pump performance over time. Recognizing this, submersible pump manufacturers are adopting high-grade alloys, duplex stainless steels, and engineered polymers to extend the lifespan of their products. These materials offer excellent resistance to pitting, erosion, and chemical degradation, which is critical for pumps operating in saline, slurry, or chemically aggressive environments.

Many manufacturers now offer material customization tailored to specific application needs, particularly in sectors such as wastewater treatment and offshore oil platforms. This adaptability enhances lifecycle value and reduces replacement frequency, reinforcing the strategic role of material innovation in modern pump engineering.

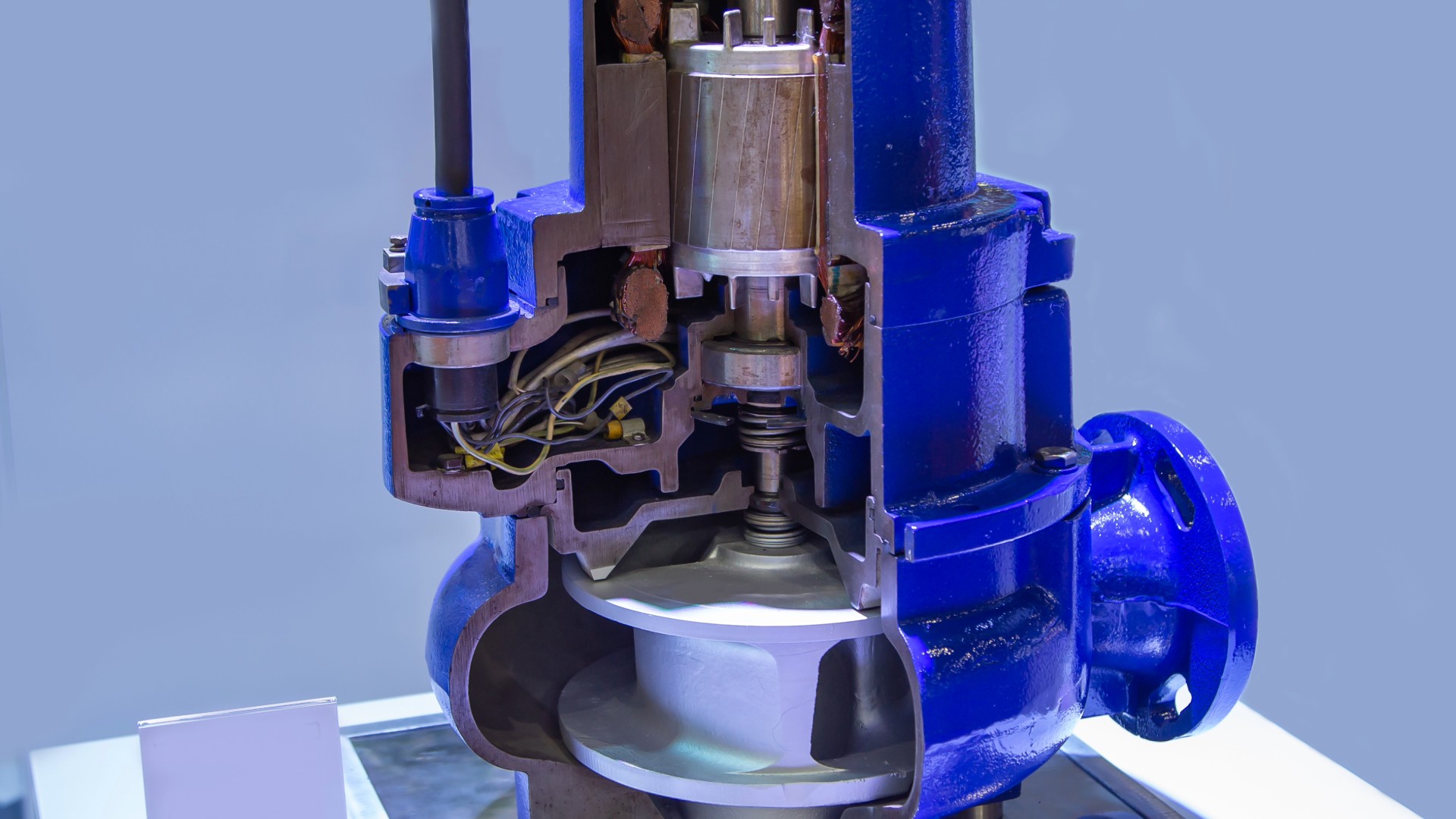

Advanced Sealing Systems

Preventing fluid ingress into motor housings is a key priority for submersible pump manufacturers, particularly in deep or high-pressure installations. Modern sealing systems utilize multi-stage mechanical seals, labyrinth configurations, and pressure-compensated oil chambers to safeguard internal components and maintain consistent performance over time.

Advanced sealing solutions from leading manufacturers support longer service intervals and reduce the risk of catastrophic motor failure. In demanding environments where pumps must operate continuously, such reliability is non-negotiable, and these innovations have become an industry standard.

High-Efficiency Motors and Winding Designs

Motor performance remains central to energy-efficient pumping. Today’s submersible pump manufacturers are introducing brushless DC motors, permanent magnet motors, and refined winding architectures that minimize energy loss while maximizing torque output. These innovations enable pumps to deliver higher hydraulic performance with lower electrical input.

Such high-efficiency motors are increasingly integrated into product offerings by major manufacturers, aligning with global mandates for reduced carbon emissions and improved energy utilization across industrial operations.

Thermal Management and Fluid Cooling

Efficient heat dissipation is vital for pump longevity, especially in high-load applications. In response, submersible pump manufacturers are refining thermal management techniques by using internal fluid circulation, heat-resistant coatings, and conduction-enhanced stator assemblies. Some designs also incorporate ferrofluid technologies to stabilize magnetic gaps and improve cooling efficiency.

These enhancements, now adopted by innovative manufacturers, ensure stable operation under thermal stress, particularly beneficial in continuous-duty cycles common to pumps used in heavy-duty environments.

Custom Solutions by Submersible Pump Manufacturers

No two operations are identical, and leading submersible pump manufacturers are embracing this by offering application-specific configurations. Whether it’s a pump built for acidic mine water, a modular system for portable flood relief, or high-pressure units for military use, customization is now a defining feature of the industry’s top players.

Pumps are being engineered for unique flow rates, temperature tolerances, and power supplies. Top manufacturers back these offerings with advanced modeling and simulation tools, ensuring that each solution fits the precise operational requirements of the end user.

Efficiency Benchmarks: Measuring What Matters

How Efficiency Is Calculated

Submersible pump efficiency is measured by comparing water output to electrical input, using the formula:

Efficiency (%) = (Water Output / Electrical Input) × 100

Submersible pump manufacturers test variables like flow rate and total dynamic head (TDH) under controlled conditions to generate reliable performance data. Leading submersible pump suppliers often include advanced diagnostic tools for verifying efficiency in the field, critical for industrial submersible pumps operating under continuous or high-energy loads.

Industry Standards

Standard pumps reach peak efficiencies around 75–80%, while premium industrial submersible pumps can exceed 90% in optimal setups. Top submersible pump manufacturers design their systems to meet global efficiency benchmarks, such as IE3 motor ratings, offering consistent performance and energy savings.

Performance Factors

Pump design is crucial, but factors such as water quality, pipe layout, and motor condition also significantly impact efficiency. Modern submersible pump suppliers address this issue by offering real-time monitoring to detect and correct efficiency drops, which is especially useful in demanding environments.

Validation and ROI

To support informed decisions, leading submersible pump manufacturers provide third-party certifications, factory test data, and performance modeling to ensure reliability and accuracy. Some also offer field validation services to ensure that industrial submersible pumps deliver the promised efficiency under actual operating conditions, safeguarding ROI.

The Future of Industrial Submersible Pumps

Modular and Adaptive Pump Systems

As demand for custom and scalable solutions grows, submersible pump manufacturers are developing modular systems that adapt to changing flow, pressure, and space requirements. These next-generation designs enable users to add or remove components, such as impeller stages, control units, or monitoring modules, without requiring the replacement of the entire system.

This modularity is particularly attractive to sectors such as oil and gas or water infrastructure, where operating conditions are subject to change. Leading submersible pump suppliers now offer adaptable configurations that simplify maintenance, reduce spare part inventories, and enable faster responses to operational changes, all while maintaining the performance standards of industrial submersible pumps.

Sustainability Integration

Sustainability is no longer a peripheral concern; it’s a procurement priority. Submersible pump manufacturers are incorporating environmentally conscious features, including energy-efficient motors, recyclable materials, and low-emission manufacturing processes. Solar-powered industrial submersible pumps are becoming more common in remote agricultural, municipal, and disaster response applications, offering off-grid reliability without environmental trade-offs.

Several top submersible pump suppliers now produce units that comply with green building certifications or government-mandated sustainability standards. These innovations enable buyers to meet corporate ESG goals while reducing long-term OPEX, making energy-optimized and eco-friendly pumps an increasingly strategic investment.

Digital Twins and AI in Pump Design

The integration of AI and digital twins is transforming how submersible pump manufacturers design and test their equipment. A digital twin is a virtual model of the pump that simulates its behavior under various conditions, allowing engineers to refine designs, predict performance, and identify potential failure points before physical production begins.

This technology enables submersible pump suppliers to offer more precise, data-backed recommendations to clients during the design phase. For complex or high-risk installations involving industrial submersible pumps, AI-enhanced modeling reduces design flaws and shortens the commissioning process, ensuring systems perform as expected from the outset.

Global Standards and Compliance Trends

Regulatory compliance and global standardization are becoming critical differentiators in the pump industry. Submersible pump manufacturers are aligning with evolving standards such as ISO 9906 for hydraulic performance, IEC energy classifications for motors, and defense procurement protocols for military-grade systems.

Buyers, especially in the public sector or large-scale industrial projects, require submersible pump suppliers to demonstrate adherence to these certifications. For industrial submersible pumps, this ensures compatibility with multi-national infrastructure guidelines and enhances confidence in product quality, safety, and performance across global markets.

What Buyers Should Expect from Leading Submersible Pump Manufacturers

Technical Guidance and System Support

Reliable submersible pump manufacturers provide technical consultation to ensure the proper selection, taking into account site conditions, flow requirements, and long-term objectives. This helps prevent sizing errors and promotes efficient operation. Some also offer layout advice and simulation-based design checks before purchase.

Verified Performance and Efficiency Data

Top manufacturers provide clear, certified efficiency ratings and third-party test results. Documentation, such as ISO-compliant reports and factory testing certificates, ensures transparency and supports regulatory compliance, particularly in energy-sensitive projects.

Built-In Monitoring Capabilities

Modern industrial pumps often come equipped with digital sensors and control interfaces. These tools track flow, temperature, and motor condition in real time, enabling better efficiency management and reduced downtime. Digital integration is becoming standard in most offerings.

After-Sales Support and Maintenance Services

Ongoing support is critical for long-term pump reliability. Leading manufacturers offer comprehensive maintenance schedules, spare parts, and expert troubleshooting support. Many also offer predictive maintenance options that use performance data to detect wear before failure occurs.

Tailored Engineering Solutions

Different sectors need different features. Top suppliers customize pumps for specific conditions, such as corrosive environments or high-pressure systems, by adjusting materials, motor types, and controls. Industry-aligned design ensures consistent performance even in demanding settings.

Choosing the Right Submersible Pump Supplier for Long-Term Value

Evaluating the Right Partner

Selecting submersible pump manufacturers should go beyond pricing. Procurement teams must assess technical knowledge, build quality, compliance, and service support. Top suppliers offer tailored solutions and maintain robust delivery capabilities, which are crucial for large-scale or time-sensitive projects.

What to Ask Your Supplier

Before finalizing, ask:

- Are efficiency ratings certified?

- What is the expected service life?

- Is smart monitoring included?

- Can the system be customized?

- What maintenance support is offered?

Submersible pump suppliers who provide transparent answers and offer documentation are more likely to meet performance and budget goals.

Total Cost Over Time

Cost-effective procurement considers total ownership cost, not just initial expense. Efficient, reliable pumps from leading submersible pump manufacturers offer better long-term value through energy savings and reduced maintenance.

How Efficiency Impacts ROI

Real-world data shows that smart, energy-efficient pump systems minimize downtime and operating expenses. Partnering with experienced submersible pump suppliers helps align infrastructure with cost, sustainability, and reliability targets.

Innovation That Delivers Performance, Efficiency, and Insight

Across today’s demanding industrial landscape, submersible pump manufacturers are redefining what performance means by integrating smart technologies, high-efficiency motors, and durable materials into every stage of product development. No longer limited to basic fluid transfer, modern industrial submersible pumps now serve as intelligent components within larger, data-driven systems, enabling operators to monitor, manage, and optimize operations in real-time.

Leading submersible pump manufacturers have embraced innovation not just for the sake of technology, but to meet the evolving needs of procurement heads, project contractors, and engineering teams seeking better ROI, lower maintenance, and system-level efficiency. By offering smart monitoring tools, predictive diagnostics, and energy-efficient designs, they are enabling decision-makers to control costs while improving uptime and reliability.

These advancements are more than incremental upgrades; they are strategic enablers that deliver quantifiable returns. Whether reducing power consumption in municipal water systems or extending service life in corrosive mining environments, high-performance solutions from forward-thinking submersible pump suppliers are making a measurable impact on bottom-line performance.

For asset managers, government buyers, and project engineers alike, aligning procurement strategies with the capabilities offered by top submersible pump manufacturers is a smart, future-ready decision. As capital investments grow more scrutinized, the ability of industrial submersible pumps to deliver long-term value through energy savings, operational resilience, and intelligent control makes them a critical asset in achieving both performance and sustainability goals.

Post a Comment