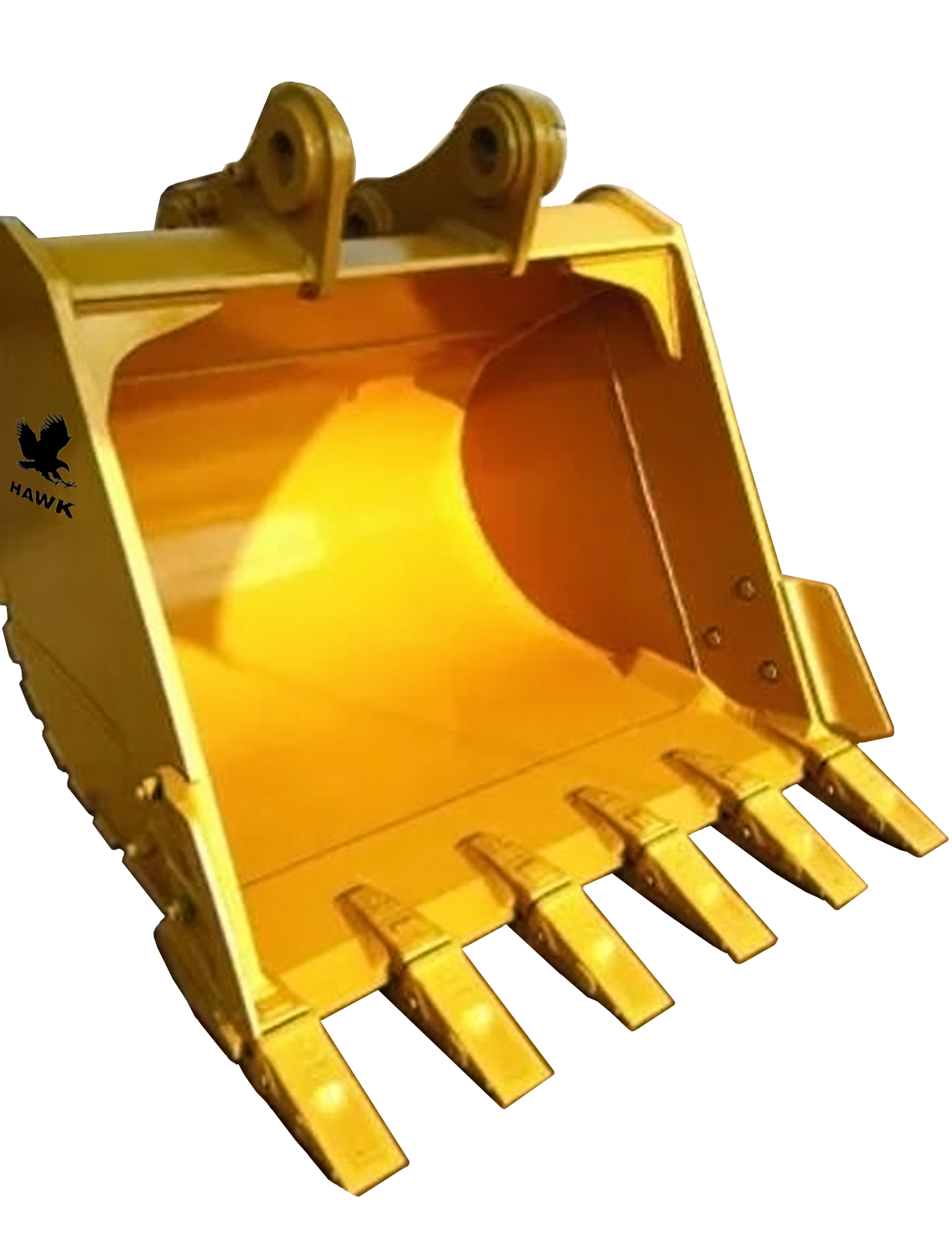

Specifications

Model: KOMPC400-HRB3554

Width: 54 inch (1372 mm)

Pin Diameter: 3.93 inch (100 mm)

Weight: 3988 lbs (1809 kg)

Material: Q355 Steel + NM400 on main blade & side cutting blade & bottom wear strip

Excavator Range: 35-44 Ton

Applications:

- Mining

- Demolition

- Construction

- Quarry

For Use On:

- Skid steer loader

- Backhoe loader

- Crane

- Telescopic handler

- Wheel loader

- Excavator

FAQs

Frequently Asked Questions – Severe Duty Bucket KOMPC400-HRB3554

What is a severe duty excavator bucket, and when should I use it?

A severe duty excavator bucket is designed for extreme applications involving hard, abrasive materials like rock, compacted soil, and gravel. You should use it in environments that require higher durability and performance, such as mining, quarrying, demolition, and heavy excavation projects.

What makes severe duty buckets different from standard or heavy-duty buckets?

Severe duty buckets are built with higher-grade steel, more wear-resistant materials, and additional reinforcement compared to standard or heavy-duty buckets. They are specifically designed for the most challenging environments and can withstand more abrasive conditions, higher impact, and prolonged wear.

How do severe duty buckets improve productivity?

Severe duty buckets feature optimized designs with aggressive teeth and cutting edges that allow for faster digging and better material retention. This results in fewer passes to move material, which improves cycle times and overall job site productivity.

Can severe duty buckets be used for all types of materials?

While severe duty buckets are optimized for abrasive and rocky materials, they can be used for a wide range of materials. However, for softer materials or lighter applications, a standard or heavy-duty bucket may be more cost-effective and efficient.

What kind of maintenance is required for severe duty buckets?

Regular inspection of wear plates, teeth, and cutting edges is essential to ensure peak performance. Severe duty buckets are built for longevity, but replacement of worn components, such as bucket teeth and side cutters, may be necessary to maintain their effectiveness.

Are severe duty buckets customizable?

Yes, severe duty buckets can be customized to meet specific application requirements. You can choose different bucket widths, capacities, and features such as additional wear plates, specialized teeth, or reinforced sidewalls to suit the needs of your project.

How do I know if my excavator is compatible with a severe duty bucket?

Severe duty buckets are available in a variety of sizes and configurations to fit most excavator models. Check your excavator’s specifications, including its weight class and coupling system, to ensure compatibility with the bucket size and type.

What are the benefits of bolt-on side cutters for severe duty buckets?

Bolt-on side cutters increase the bucket’s cutting width and provide additional protection for the sidewalls. They are replaceable, which allows you to maintain the bucket’s performance and extend its lifespan, especially when working in abrasive environments.

How do severe duty buckets handle high-impact environments?

Severe duty buckets are designed with reinforced steel, extra wear plates, and robust teeth to handle high-impact forces from digging into rocky, compacted, or abrasive materials. This ensures the bucket resists cracking or deformation, even in the most demanding conditions.

Can I replace parts like bucket teeth and wear plates on severe duty buckets?

Yes, most severe duty buckets come with replaceable bucket teeth, side cutters, and wear plates. Regular maintenance and timely replacement of these components help extend the bucket’s lifespan and ensure optimal performance over time.

Reviews

There are no reviews yet.