Introduction

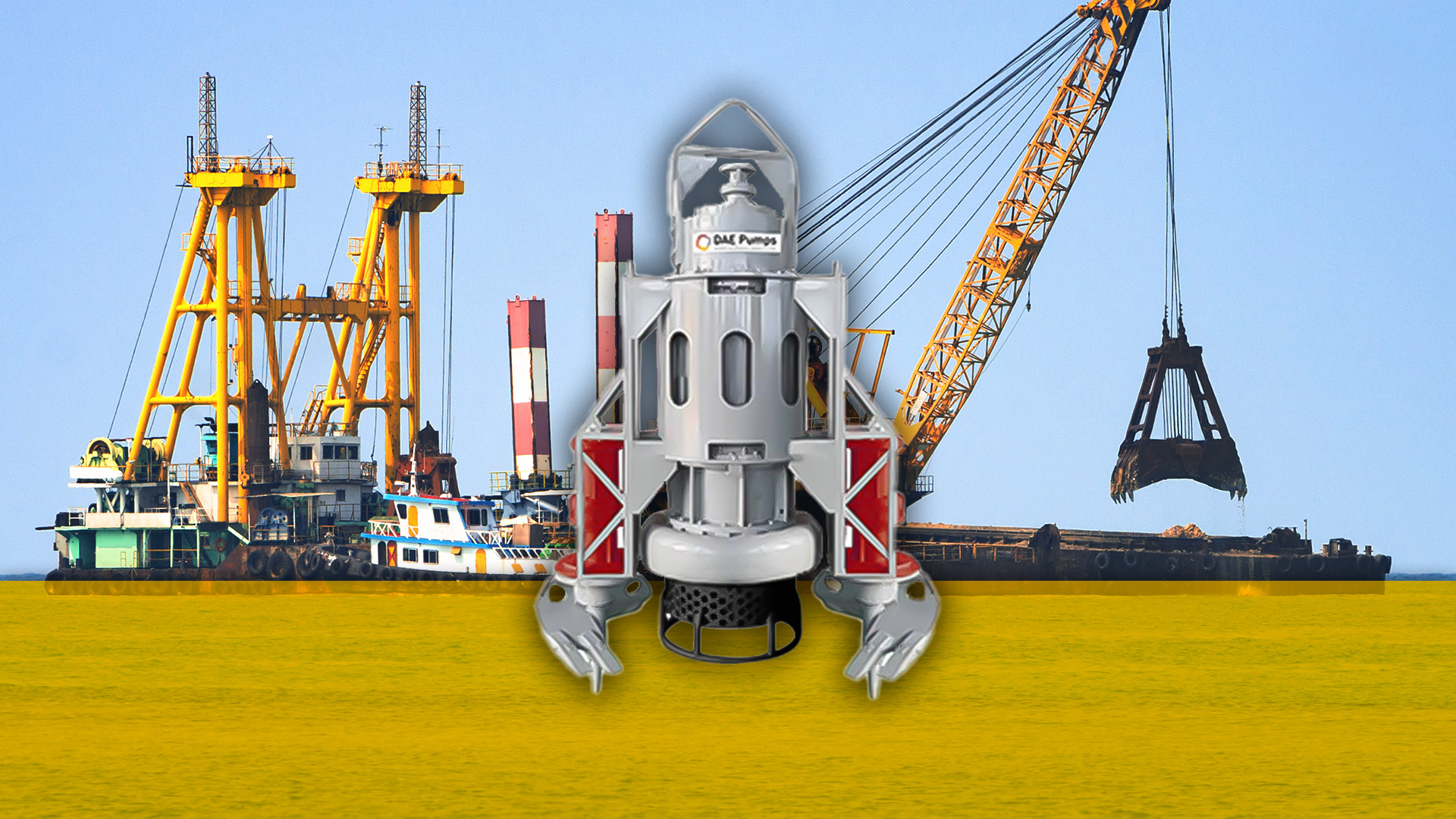

Dredge pumps play a crucial role in various industrial applications, from mining and construction to environmental remediation. These powerful machines are essential for moving large volumes of slurry, sediment, and other materials. However, choosing the right type of dredge pump can significantly impact the efficiency and success of your operation. In this article, we will explore the differences between electric and hydraulic dredge pumps, helping you determine which type is best suited for your needs.

Section 1: Understanding Dredge Pumps

Dredge pumps are specialized pumps designed to handle the abrasive and dense nature of slurry and sediment. They are commonly used in dredging operations to remove sediment from water bodies, extract minerals, or reclaim land. The primary function of a dredge pump is to transport these materials through pipelines to a designated location for disposal or processing.

Common Applications of Dredge Pumps

- Mining: Extracting minerals and transporting them for further processing.

- Construction: Removing sediment from construction sites or water bodies.

- Environmental Remediation: Cleaning up contaminated sediments and restoring natural habitats.

- Land Reclamation: Reclaiming land from water bodies by removing sediments.

Section 2: Overview of Electric Dredge Pumps

Description and Operation

Electric dredge pumps are powered by electric motors. These pumps are known for their reliability and efficiency. The electric motor drives the pump impeller, which generates the suction needed to move the slurry through the system.

Key Components

- Electric Motor: Provides the power to drive the pump.

- Pump Impeller: Creates the suction force to move the slurry.

- Control Systems: Regulate the pump’s operation and monitor performance.

Advantages of Electric Dredge Pumps

- Energy Efficiency: Electric motors are highly efficient, converting most of the electrical energy into mechanical energy.

- Lower Maintenance Requirements: Electric pumps have fewer moving parts, reducing the need for frequent maintenance.

- Reduced Environmental Impact: Electric pumps produce no emissions, making them more environmentally friendly.

Limitations of Electric Dredge Pumps

- Dependency on Power Supply: Electric pumps require a consistent and reliable power source, which can be a limitation in remote locations.

- Potentially Higher Initial Costs: The cost of electric pumps and the infrastructure needed for power supply can be higher compared to hydraulic systems.

Section 3: Overview of Hydraulic Dredge Pumps

Description and Operation

Hydraulic dredge pumps are powered by hydraulic systems. These pumps use hydraulic fluid to transfer power from a hydraulic motor to the pump impeller. Hydraulic pumps are known for their high power output and versatility.

Key Components

- Hydraulic Motor: Drives the pump using hydraulic fluid.

- Pump Impeller: Generates the suction force to move the slurry.

- Hydraulic Fluid: Transfers power from the motor to the pump.

Advantages of Hydraulic Dredge Pumps

- High Power Output: Hydraulic pumps can generate significant power, making them suitable for heavy-duty applications.

- Flexibility and Mobility: Hydraulic systems are often more portable and can be used in remote and off-grid locations.

- Suitable for Remote Locations: Hydraulic pumps do not rely on an electric power grid, making them ideal for isolated areas.

Limitations of Hydraulic Dredge Pumps

- Higher Maintenance Needs: Hydraulic systems require regular maintenance to ensure the integrity of hydraulic lines and components.

- Potential for Environmental Hazards: Leaks of hydraulic fluid can pose environmental risks and require careful management.

Section 4: Performance Comparison

Efficiency and Power Output

- Electric Pumps: Generally more energy-efficient, converting electrical energy directly into mechanical energy.

- Hydraulic Pumps: Capable of higher power outputs, suitable for demanding applications.

Maintenance and Durability

- Electric Pumps: Require less maintenance due to fewer moving parts.

- Hydraulic Pumps: Require regular maintenance of hydraulic lines and components.

Environmental Considerations

- Electric Pumps: Produce no emissions and have a smaller environmental footprint.

- Hydraulic Pumps: Potential for hydraulic fluid leaks, which can be environmentally hazardous.

Cost Analysis

- Initial Investment: Electric pumps may have higher initial costs due to the need for power infrastructure.

- Operational Costs: Electric pumps are generally more cost-effective in terms of energy consumption.

Section 5: Factors to Consider When Choosing Between Electric and Hydraulic Dredge Pumps

Nature of the Operation

- Location: Consider the availability of power sources and the remoteness of the operation.

- Scale: The size and scope of the project can influence the choice of pump.

Power Supply Availability and Reliability

- Electric Pumps: Suitable for areas with reliable power infrastructure.

- Hydraulic Pumps: Ideal for off-grid and remote locations.

Budget Constraints

- Initial Costs: Evaluate the upfront investment required for both types of pumps.

- Operational Costs: Consider long-term costs associated with energy consumption and maintenance.

Environmental Regulations and Sustainability Goals

- Electric Pumps: Preferable for operations with stringent environmental regulations.

- Hydraulic Pumps: Suitable for projects where power independence is crucial.

Maintenance Capabilities and Resources

- Electric Pumps: Require less frequent maintenance, suitable for operations with limited maintenance resources.

- Hydraulic Pumps: Need regular maintenance, requiring skilled personnel and resources.

Section 6: Expert Opinions and Recommendations

Insights from Industry Experts

- Quotes and opinions from professionals in the dredging industry on the advantages and disadvantages of both types of pumps.

Recommendations for Specific Scenarios

- Urban Projects: Electric pumps are recommended due to their efficiency and environmental benefits.

- Remote Operations: Hydraulic pumps are ideal for their power and independence from the power grid.

Conclusion

Choosing between electric and hydraulic dredge pumps depends on various factors, including the nature of the operation, power availability, budget constraints, and environmental considerations. By assessing these factors, you can determine which type of pump is best suited for your specific needs.

Post a Comment