Description

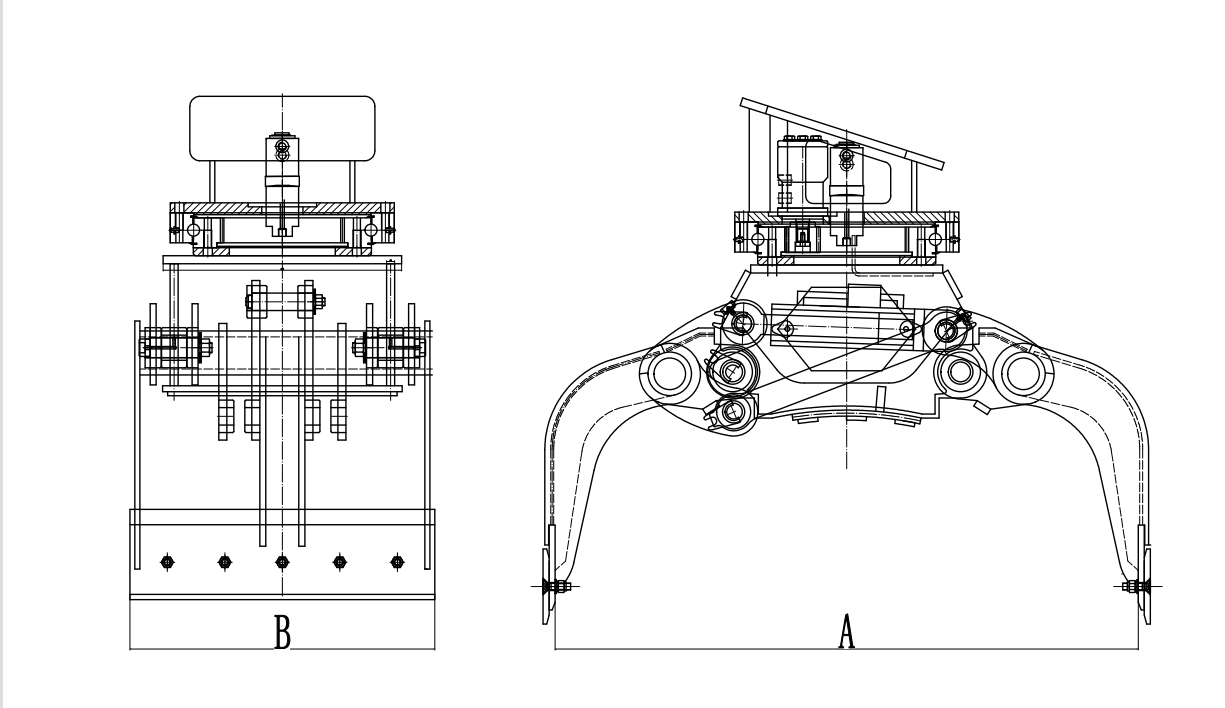

The HAWK Excavator RHG80 rotating hydraulic grapple series excels in construction and material re-handling tasks, offering versatility to meet diverse operational requirements. Featuring precision grip and high maneuverability, it ensures swift and efficient task completion.

Designed for Excavators up to 11 tons, HAWK’s RHG80 rotating hydraulic grapple is renowned for its efficiency, durability, and quality. Customers can tailor their equipment based on various parameters, ensuring optimal performance and operational compatibility.

- Excavator Range: 5-11 Ton

- Working Conditions: Suitable for operations such as excavation and loading of wood, brick, and loose materials.

Benefits of Rotating Hydraulic Grapples

Rotating hydraulic grapples offer unparalleled functionality and versatility, rendering them indispensable tools for a variety of heavy-duty applications. Here are the key advantages of utilizing rotating hydraulic grapples:

360-Degree Rotation: The continuous 360-degree rotation capability facilitates precise positioning and manipulation of materials, enhancing maneuverability and efficiency, particularly in confined or complex environments.

Enhanced Versatility: Rotating hydraulic grapples find utility across a broad spectrum of applications, including demolition, material sorting, waste handling, and forestry, owing to their unmatched flexibility enabled by rotation.

Improved Efficiency: The hydraulic rotation mechanism significantly enhances operational efficiency by minimizing the time and effort required to reposition materials, thereby increasing productivity and reducing operational costs.

Superior Grip and Control: Equipped with robust hydraulic cylinders, these grapples afford a secure grip on various materials, ensuring safe and efficient handling. The precise control enables operators to manage delicate or heavy materials with ease, mitigating the risk of damage.

Durable Construction: Constructed from high-strength, wear-resistant materials, rotating hydraulic grapples exhibit durability and long-term performance even in the most demanding working conditions, thereby reducing the need for frequent maintenance and replacements.

Increased Safety: The secure gripping mechanism and precise hydraulic control provided by these grapples enhance job site safety by minimizing the likelihood of accidental drops or mishandling, thereby mitigating potential hazards.

Adaptability to Various Machines: These grapples boast compatibility with a wide array of excavators and other heavy machinery, making them versatile additions to any equipment fleet. Their adaptability ensures seamless integration with diverse equipment types.

Reduced Operator Fatigue: The hydraulic operation and ergonomic control features mitigate physical strain on operators, resulting in decreased fatigue and heightened productivity. This ergonomic advantage is pivotal for sustaining operator efficiency during prolonged usage.

Features of Rotating Hydraulic Grapples – RHG80

Rotating hydraulic grapples such as the RHG80 are meticulously engineered to deliver superior performance and versatility in demanding material handling applications. Here are the standout features that distinguish these grapples as indispensable tools for heavy-duty operations:

360-Degree Continuous Rotation: These grapples are equipped with a robust hydraulic rotator enabling seamless 360-degree rotation, facilitating precise material positioning and manipulation from any orientation for heightened operational flexibility and efficiency.

Powerful Hydraulic Cylinders: Featuring potent hydraulic cylinders, rotating hydraulic grapples exert substantial gripping force, ensuring a secure hold on a diverse range of materials, from heavy debris to delicate items, thereby enhancing handling accuracy and safety.

Replaceable Wear Parts: Essential components such as cutting edges and tips are designed for easy replacement, extending the grapple’s lifespan and minimizing maintenance downtime, thus ensuring uninterrupted operation.

Optimized Jaw Design: Engineered for optimal penetration and gripping efficacy, the jaws incorporate interlocking teeth that firmly grasp irregularly shaped materials, enhancing productivity in sorting and handling operations.

Enhanced Hydraulic System: The advanced hydraulic system integrates pressure relief valves and flow control mechanisms, guaranteeing smooth and efficient operation while safeguarding the grapple from hydraulic overload for maximized performance.

Universal Mounting Compatibility: Thanks to their universal mounting system, rotating hydraulic grapples seamlessly integrate with a wide array of excavators and machinery, facilitating effortless attachment and detachment for swift transitions between different equipment and tasks.

Protective Hoses and Fittings: Strategically positioned and shielded hydraulic hoses and fittings mitigate the risk of damage during operation, minimizing the possibility of hydraulic fluid leaks and extending the lifespan of hydraulic components.

Sealed Bearings and Joints: All bearings and joints are sealed to prevent ingress of dirt and debris, thereby reducing wear and tear and prolonging the grapple’s service life, ensuring consistent performance in harsh operational environments.

Enhanced Operator Visibility: Prioritizing operator visibility, the grapple’s design enables better control and accuracy during material handling operations, reducing operator fatigue and enhancing overall job site safety.

These features collectively position rotating hydraulic grapples as versatile and reliable attachments suitable for a broad spectrum of material handling tasks, ranging from demolition and construction to waste management and recycling. With their robust construction, powerful performance, and user-friendly design, they constitute a valuable addition to any heavy equipment fleet.

Reviews

There are no reviews yet.